Top Wire Supply Trends to Watch in 2026?

As we look ahead to 2026, the landscape of wire supply is poised for significant change. Various factors will shape this industry, affecting both producers and consumers. Trends in technology, sustainability, and global demand will heavily influence the direction of wire supply.

Wire supply chains face challenges, including sourcing materials responsibly. Innovations may lead to new products, but the industry must reflect on environmental implications. For instance, companies are exploring recycled materials, yet the effectiveness of these efforts varies.

Additionally, shifts in consumer preferences are indispensable. As industries prioritize green solutions, wire supply must adapt or risk falling behind. The conversation surrounding sustainability is crucial. The future of wire supply will require active engagement and reflection on current practices to remain relevant.

Top Wire Supply Trends to Watch in 2026: An Overview

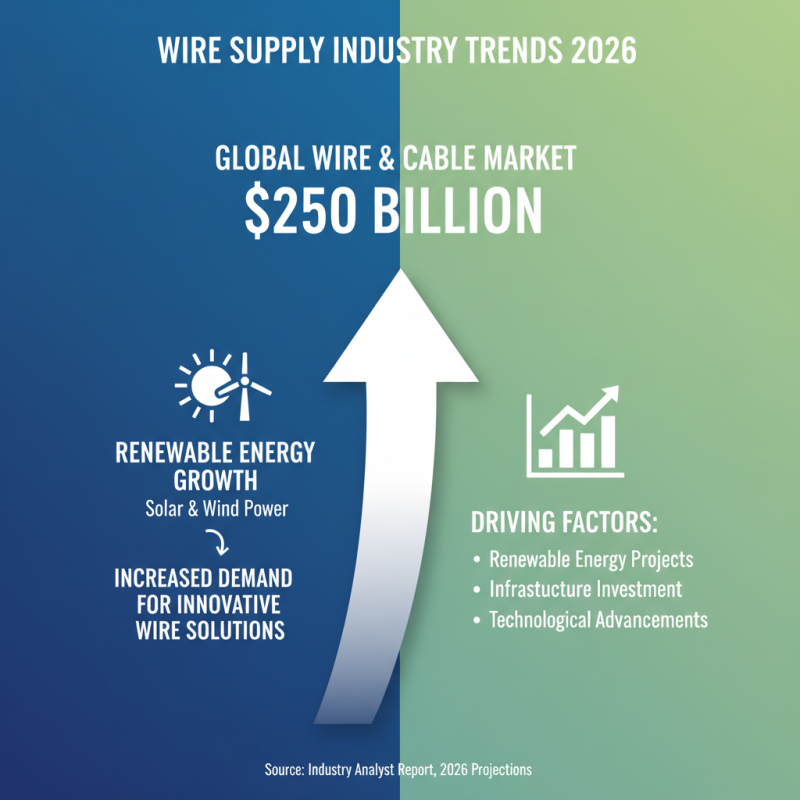

As we approach 2026, significant trends are emerging in the wire supply industry. The growth of renewable energy projects is driving demand for specific wire types. According to a recent report by industry analysts, the global wire and cable market is expected to reach $250 billion by 2026. This shift is partly due to increased investments in solar and wind energy, requiring innovative wire solutions.

Another noteworthy trend is the rise of smart technologies in wire applications. The integration of Internet of Things (IoT) capabilities is essential for modern wire systems. Analysts predict that IoT-connected devices will witness a compounded annual growth rate (CAGR) of 25% by 2026. This means a surge in demand for wires that can support smart infrastructure. However, the industry faces challenges, such as supply chain disruptions and material shortages, which could hinder progress.

Sustainability is also a pressing concern. Many companies are reevaluating their manufacturing processes to reduce environmental impact. Reports indicate that 40% of manufacturers plan to adopt green technologies in their wire production by 2026. This shift may improve company reputations and meet customer demands. Yet, moving towards sustainable practices may also involve higher initial costs and operational adjustments, which can be daunting for many.

Industry Growth Projections for Wire Supply Sector by 2026

As we look ahead to 2026, the wire supply sector shows promising growth. Various industries are ramping up demand for wiring solutions. This trend is driven by advancements in technology and infrastructure development. Electric vehicles and renewable energy projects require better wiring materials. These sectors will shape the market heavily.

However, challenges remain. Supply chain disruptions could hinder growth. Fluctuations in raw material prices may also impact production costs. Moreover, meeting sustainability goals poses another obstacle. Companies must adapt to eco-friendly manufacturing practices. This shift might slow down some operations, causing delays.

Despite these hurdles, opportunities abound. The increasing need for connectivity in smart homes will drive innovation. Additionally, industries focusing on automation and smart technologies will require enhanced wire solutions. Companies should remain flexible and ready to pivot. The path to growth is not without its bumps, but it is achievable with careful planning and adaptation.

Emergence of Sustainable Materials in Wire Manufacturing

As we look to 2026, the wire manufacturing industry is witnessing significant changes. The move toward sustainable materials is reshaping production processes. According to recent industry reports, the market for eco-friendly wire materials is projected to grow by 20% annually. This trend is driven by increasing consumer awareness and regulatory pressures.

Biodegradable polymers and recycled metals are gaining traction. These materials not only reduce waste but also offer competitive performance. In fact, recycled aluminum can reduce energy consumption by up to 95%. Many manufacturers face challenges in integrating these materials into existing production lines. The transition is complex and requires investment in new technologies.

Despite progress, there are hurdles. Sustainable alternatives often come with higher costs. This poses a dilemma for companies keen on sustainability yet bound by profit margins. Additionally, the long-term durability of new materials remains under scrutiny. Each choice made reflects a commitment to a greener future, yet the industry must remain adaptable.

Technological Innovations Driving Wire Production Efficiency

In 2026, technology will shape the wire production landscape. Automation will play a key role. Robots are expected to increase efficiency. They can operate continuously without breaks. This could reduce costs and improve quality. However, we must consider the initial investment. High-tech machinery can be expensive to install.

Another trend is the use of data analytics. Real-time monitoring of production processes will enhance decision-making. Sensors can track material quality. This leads to fewer defects and waste. But data management remains a challenge. Companies must address cybersecurity issues.

Sustainability will push innovations. New materials may replace traditional wires. These alternatives should be eco-friendly yet strong. Yet, the transition could be tricky. Not every company is ready to adapt. Old habits die hard, and change takes time. Embracing these trends requires careful thought and planning.

Impact of Global Supply Chain Dynamics on Wire Availability

In 2026, the availability of wire is heavily influenced by global supply chain dynamics. Current reports indicate that the wire industry faces challenges due to fluctuating raw material costs and geopolitical tensions. For instance, copper prices have soared by over 30% in the past two years. This volatility impacts not only suppliers but manufacturers as well.

Logistical hurdles add to the complexity. Shipping delays and increased freight costs can disrupt the supply of essential materials. An analysis from an industry expert suggests that it takes about 60% longer to source wire materials compared to three years ago. These issues are not just temporary; they may dictate future sourcing strategies.

Tips: Always maintain a flexible supply chain strategy. Explore alternative sourcing regions to mitigate risk. Consider adopting local suppliers for critical wire materials to reduce dependency. This approach can increase resilience in uncertain market conditions. Remember to continuously reassess your inventory levels. A proactive stance can prevent shortages and keep production running smoothly.

Top Wire Supply Trends to Watch in 2026

| Trend | Impact on Supply | Expected Growth Rate (%) | Region Affected | Opportunities |

|---|---|---|---|---|

| Sustainable Materials | Increase in availability of eco-friendly wires | 25% | Global | Expansion into green technology |

| Automation in Production | Improved efficiency leading to higher output | 30% | North America, Europe | Investments in smart manufacturing |

| Digital Supply Chain Management | Real-time monitoring and reduced delays | 20% | Asia-Pacific | Improved collaboration and transparency |

| Resilient Sourcing Strategies | Diverse supply sources to mitigate risks | 15% | Global | Reduced dependency on single suppliers |

| Advanced Material Science | New alloys and composites improving performance | 18% | Europe, North America | Higher durability products for industry |

Related Posts

-

How to Choose the Best Cable Solutions for Your Home and Office Needs

-

Why Airplane Wire is Essential for Aviation Safety?

-

Top 10 Aircraft Wire Types and Their Applications Explained

-

Understanding the Role of Wire Cable Connectors in Modern Technology Systems

-

Top 2025 Lead Wire Innovations: Trends, Applications, and Future Insights

-

Essential Tips for Understanding Lead Cable Applications?