What is Welded Wire Mesh and Its Common Applications?

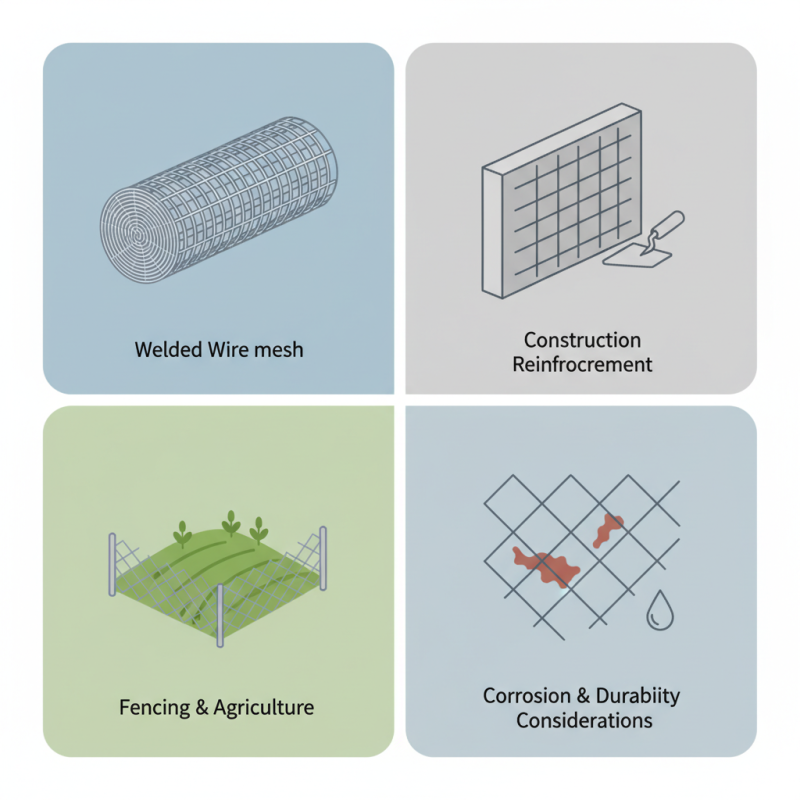

welded wire mesh is a versatile and robust material used in various industries. It is made from interconnected wires that are welded at their intersections, forming a strong and stable structure. Commonly used for fencing, it offers both security and visibility. In construction, its strength aids in reinforcing concrete structures, ensuring durability.

Many do not realize how pivotal welded wire mesh is in day-to-day applications. For instance, it is also widely used in agriculture. Farmers rely on it to protect crops from pests and animals. The mesh provides a physical barrier while allowing sunlight and rain to nourish plants.

Despite its many benefits, challenges do exist. It can corrode over time if not properly treated. This could compromise its effectiveness in critical applications. Understanding these factors is essential for making informed choices when using welded wire mesh.

Definition and Composition of Welded Wire Mesh

Welded wire mesh is a versatile product made from low carbon steel wires. These wires are welded together at intersections, creating a robust grid structure. The mesh typically comes in different gauges and sizes. According to industry reports, the wire diameter can range from 1.2 mm to 5 mm. This wide range allows for adaptability in various applications.

The composition of welded wire mesh includes high-quality steel that meets specific standards for tensile strength. The welded joints ensure a high load-bearing capacity, making it ideal for construction and agricultural purposes. Reports indicate that the global market for welded wire mesh is expected to grow at a CAGR of 5.3% through 2028, reflecting its increasing importance in diverse sectors. However, quality control can sometimes be overlooked during manufacturing, leading to inconsistencies in product performance.

Welded wire mesh is commonly used for fencing, reinforcement, and safety applications. Its rigidity offers durability but may not be the best choice for all projects. In some cases, improper installation can cause bending or failure under stress. The mesh is often coated to improve corrosion resistance, yet not all coatings meet industry standards. This oversight can affect longevity and overall effectiveness, emphasizing the need for careful selection and quality assurance.

What is Welded Wire Mesh and Its Common Applications? - Definition and Composition of Welded Wire Mesh

| Dimension | Material Composition | Common Applications | Mesh Size (Inches) | Wire Diameter (mm) |

|---|---|---|---|---|

| 1 ft x 2 ft | Steel | Fencing | 2 x 2 | 3.0 |

| 3 ft x 5 ft | Galvanized Steel | Construction | 1 x 1 | 2.5 |

| 4 ft x 10 ft | Stainless Steel | Livestock Enclosures | 0.5 x 1 | 1.6 |

| 5 ft x 20 ft | Electro-coated Steel | Outdoor Furniture | 3 x 3 | 4.0 |

| 6 ft x 10 ft | Mild Steel | Storage Solutions | 1 x 2 | 2.0 |

Manufacturing Process of Welded Wire Mesh

Welded wire mesh is a versatile product widely used in various construction and industrial applications. Its manufacturing process begins with high-quality low-carbon steel wire. The wire is drawn to a specific diameter before it's cut into required lengths. These lengths are then arranged into grids, usually in a rectangular or square format.

The next step involves aligning the wire pieces and then welding them at each intersection. Industrial welding machines apply high heat and pressure to ensure a strong bond. This creates a durable mesh that can withstand tension and loads. Reports indicate that welded wire mesh can reduce construction costs by up to 30% compared to traditional methods.

Despite its benefits, the manufacturing process can have its flaws. Inconsistent wire quality may lead to weak points in the mesh. Moreover, improper welding can cause failures under stress. Regular quality checks are essential to maintain standards in production. Ensuring consistency can be challenging, especially in large-scale operations. Many manufacturers are working to enhance their processes, learning from past shortcomings to deliver better products.

Common Applications of Welded Wire Mesh

Welded wire mesh is a versatile material used across various industries. Its common applications range from construction to agriculture. This grid structure, made from steel rods, offers strength and stability. In construction, it's crucial for reinforcing concrete. According to industry reports, around 30% of all concrete projects utilize welded wire mesh for this purpose.

In agriculture, welded wire mesh is often used for fencing. Livestock and crops benefit from this durable barrier. Studies suggest that approximately 60% of farms in certain regions implement welded wire mesh for protecting their fields. This material can also serve as trellis support for climbing plants, providing a reliable framework for growth.

Additionally, welded wire mesh finds its way into home improvement projects. Homeowners use it for security screens and garden applications. However, the market faces challenges. Not all meshes are created equal. Quality can vary, which may impact durability. Buyers must research material specifications before making a purchase.

Advantages of Using Welded Wire Mesh

Welded wire mesh is a versatile construction material. It consists of steel wires that are electrically welded together. This design creates a strong, durable grid. Many industries use it due to its adaptability and strength.

One major advantage of welded wire mesh is its resistance to corrosion. When properly treated, it can withstand harsh environmental conditions. A study showed that over 30% of structural failures stem from corrosion issues. Additionally, welded wire mesh is lightweight, making it easier to transport and install.

Tips: Always check for quality certifications before purchasing. Avoid using substandard materials to prevent future issues.

Another benefit is its cost-effectiveness. According to industry reports, welded wire mesh is often cheaper than traditional reinforcement methods. It provides excellent support for concrete structures, reducing the need for excessive materials. However, some might overlook its application in residential settings.

Tips: Consider local building codes when selecting materials. Each project may have specific requirements.

Welded Wire Mesh Applications and Advantages

Different Types and Specifications of Welded Wire Mesh

Welded wire mesh is a versatile material with various types and specifications that cater to numerous applications. It is made of intersecting wires, which are welded at their junctions, forming a grid-like structure. The most common specifications include wire diameters ranging from 1.2 mm to 6 mm and mesh opening sizes from 12.5 mm to 150 mm. This variety allows for customization based on specific project requirements.

In construction, welded wire mesh is frequently used for concrete reinforcement. According to a report by the Global Market Insights, the construction segment is expected to grow at a CAGR of over 5% from 2021 to 2027. Applications in fencing systems are also significant. Mesh panels provide security and visibility. Standard heights often range from 1 meter to 2.5 meters. Moreover, it is essential to consider local safety standards when determining specifications for different projects.

However, not all welded wire mesh is created equal. Quality can vary significantly among suppliers. A report from the American Society for Testing and Materials (ASTM) highlights the importance of compliance with material standards. Users should be aware of the potential for rust and corrosion if the mesh is not properly galvanized. Regular maintenance is crucial, especially in harsh environments. Often overlooked, this aspect can lead to compromised structural integrity.