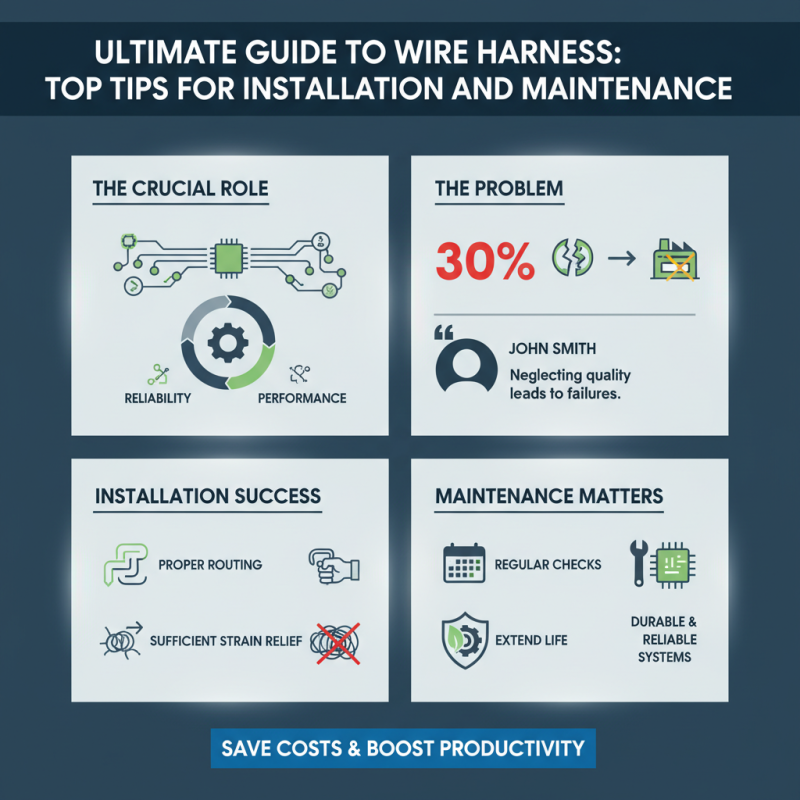

Ultimate Guide to Wire Harness Top Tips for Installation and Maintenance

In the rapidly evolving world of electronics, the wire harness plays a crucial role. It connects various components, ensuring reliability and performance. Recent industry studies indicate that approximately 30% of electrical failures in machinery can be traced back to issues with wire harnesses. This statistic highlights the importance of proper installation and maintenance practices.

John Smith, a renowned expert in wire harness technology, states, “Neglecting the quality of wire harnesses can lead to catastrophic failures.” His insight reflects a key reality in the industry. Many manufacturers overlook the significance of a well-constructed wire harness. This can result in costly repairs and lost productivity.

Understanding the intricacies of wire harness installation is essential for success. Common installation mistakes can include improper routing and insufficient strain relief. Regular maintenance can mitigate these issues, extending the life of the harnesses. By prioritizing these practices, companies can avoid substantial setbacks. The focus should remain on creating durable and reliable wire harness systems.

Understanding Wire Harness: Components and Functions

A wire harness plays a crucial role in connecting various electrical components. Understanding its components helps in installation and maintenance. Wire harnesses usually include wires, connectors, and protective coverings. Each element serves a specific function, ensuring safety and efficiency.

Here are some tips for maintaining your wire harness. Regularly inspect for wear and tear. Look for frayed wires or loose connectors. Any signs of damage should be addressed immediately. A small issue can lead to significant failures. Keep the installation area clean. Dirt and moisture can cause corrosion, affecting performance.

Remember to route wires carefully. Sharp bends or excessive tension can weaken the harness over time. Use proper fasteners. They keep everything in place and protect against vibrations. Over time, even the best installations can show signs of fatigue. Staying proactive is essential.

Wire Harness Installation and Maintenance Tips

Preparing for Installation: Tools and Safety Measures

Preparing for a wire harness installation requires careful attention to tools and safety measures. A good starting point is to gather essential tools. Wire cutters, crimpers, and a multimeter are indispensable. Additionally, having a heat gun can help with heat shrink tubing. Ensure all tools are in good condition. Check for any wear and tear. An unnoticed defect may lead to complications during installation.

Safety is paramount during the installation process. Always wear safety glasses to protect your eyes from tiny wire fragments. Keep your workspace tidy to avoid accidents. A cluttered area can lead to mistakes. It’s also wise to wear gloves, especially when handling sharp objects. Ensure your workspace is well-lit. Poor visibility could hinder your ability to see details and identify issues.

Before diving into installation, take a moment to review your plan. Read through the diagrams carefully. It’s easy to overlook a crucial step. Mistakes are often made due to rushing. If something doesn’t feel right, pause and reassess your approach. This simple practice can save time and resources.

Ultimate Guide to Wire Harness Top Tips for Installation and Maintenance - Preparing for Installation: Tools and Safety Measures

| Tool/Item | Purpose | Safety Measure |

|---|---|---|

| Wire Stripper | To strip insulation from wires | Always wear eye protection |

| Crimping Tool | To secure connectors to wires | Inspect tools for damage before use |

| Soldering Iron | To create permanent electrical connections | Use in well-ventilated area |

| Heat Shrink Tubing | To provide insulation over connections | Ensure tubing is appropriate size before use |

| Multimeter | To measure voltage, current, and resistance | Follow electrical safety guidelines when testing |

| Electrical Tape | To secure and insulate wire connections | Ensure connections are clean and dry before applying |

Step-by-Step Installation Process for Wire Harnesses

Installing a wire harness can be straightforward if you follow a clear process. Begin by gathering all necessary tools and materials. Ensure you have wire strippers, crimpers, and plenty of zip ties. The workspace should be clean and well-lit. This helps prevent mistakes. Evaluate the layout before starting. Visualize where each wire will go.

Start by connecting the wires. Strip about half an inch of insulation off each end. Twist the wires together if they are to be joined. Use crimp connectors for secure connections. Do not rush this process. Check each connection carefully; a loose connection can lead to malfunctions later. Use zip ties to manage excess wire. A tidy installation reduces the chance of wear and tear.

As you wrap up, conduct a final inspection. Look for any exposed wires or loose connections. This is a good time to reflect on the installation. Were there any challenges? Did you notice any areas for improvement? Document your experience for future installations. The details matter, and learning from the process is key.

Common Issues in Wire Harness Maintenance and Troubleshooting

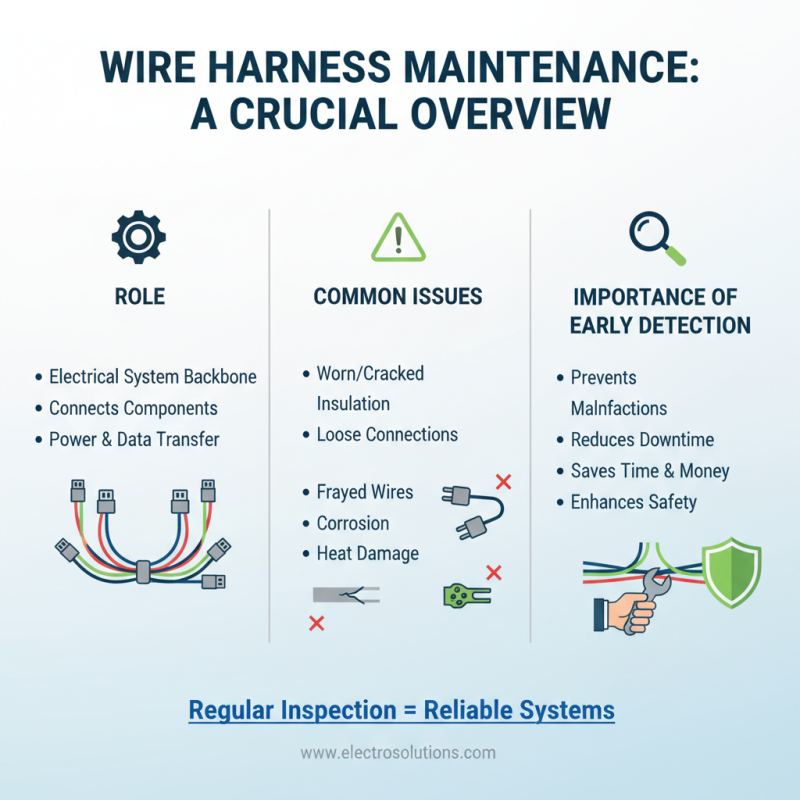

Wire harnesses play a crucial role in any electrical system. However, maintenance can often be overlooked. Common issues like worn insulation or loose connections can lead to serious problems. Identifying these issues early can save you time and money.

Tips for maintenance include regular inspections. Check for signs of fraying. Look for corrosion on connectors. Clean any dirt or debris buildup. It’s essential to address these problems immediately. Neglecting them can lead to system failures.

Another important aspect is proper installation. Ensure that the harness is routed carefully. Avoid sharp edges and sources of heat. Use cable ties to secure loose wires. This helps prevent damage and wear over time. Remember, even small mistakes can lead to significant issues down the road. Stay vigilant. Regular maintenance ensures reliability.

Best Practices for Long-Term Care and Inspection of Wire Harnesses

When it comes to wire harnesses, long-term care is crucial. Regular inspection helps to prevent costly failures. Research shows that 30% of electrical failures in vehicles result from poor wire harness maintenance. The complexity of modern wiring systems demands a proactive approach. Inspect connections for signs of wear or corrosion. This can save time and money over the lifespan of the harness.

Ensure that you document any issues during inspections. This provides a clearer view of the harness’s condition over time. According to industry reports, lack of proper records can lead to oversights in maintenance. Establish a routine check-up schedule. Frequent inspections are vital, at least once every six months.

Environmental factors can impact wire harness longevity. Exposure to heat, moisture, and dirt should be monitored. Sealants can protect harnesses from moisture, but they come with their own risks. Improper application can trap moisture inside, causing damage. Use caution and ensure proper techniques. A wired system that is well cared for can last significantly longer than its poorly maintained counterpart.

Related Posts

-

Top 10 Cable Connectors You Need for Your Electronics Projects

-

Understanding the Importance of Cable Clamps in Modern Electrical Installations

-

Understanding the Essentials of Cable Harness: A Comprehensive Guide for Beginners

-

How to Choose the Right Wire Cable for Your Electrical Projects

-

How to Choose the Best Cable Solutions for Your Home and Office Needs

-

How to Use Wire Clips for Organizing Cables and Enhancing Safety at Home