2025 Top Cable Harness Innovations and Trends You Need to Know

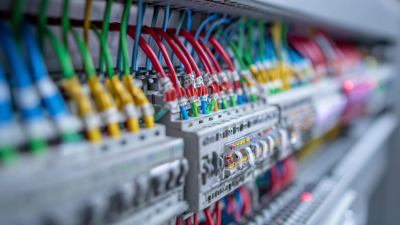

As we approach 2025, the cable harness industry is poised for remarkable innovations and trends that are set to redefine the landscape. According to the latest report by MarketsandMarkets, the cable harness market is projected to reach USD 51.23 billion by 2025, growing at a CAGR of 7.89%. This growth is indicative of the increasing demand for efficient wiring systems across various sectors, particularly in automotive, aerospace, and consumer electronics.

Industry experts, like Dr. Emily Hartwell from the Global Cable Harness Association, emphasize the significance of these advancements: "Understanding the evolving trends in cable harness technology is essential for companies to remain competitive. The innovations we are witnessing not only enhance performance but also drive cost efficiency." As companies strive to integrate smart technologies and sustainable practices, their focus on optimizing cable harness designs is more crucial than ever. The next few years will reveal transformative changes that promise to boost productivity, safety, and environmental sustainability in the manufacturing process.

In this exploration of the top 10 cable harness innovations for 2025, we will delve into the key trends set to emerge, the technological breakthroughs driving these changes, and the potential impacts on various industries.

Emerging Smart Technologies Revolutionizing Cable Harness Design By 2025

As we approach 2025, the cable harness industry is on the brink of transformation driven by emerging smart technologies. Innovations such as AI-based cable design software and predictive analytics are enabling manufacturers to streamline the design process, resulting in faster production times and reduced costs. These intelligent tools allow engineers to simulate various environmental conditions and loading scenarios, significantly enhancing reliability and performance assessments.

Moreover, the integration of IoT devices within cable harness systems is set to redefine operational efficiency. By embedding sensors into cable harnesses, companies can monitor system performance in real-time, predictive maintenance can be implemented, and potential failures can be addressed before they result in costly downtime. Such advancements not only improve the overall longevity of cable harnesses but also enable smarter, more adaptable designs that cater to the ever-evolving demands of industries like automotive and aerospace. As these innovations continue to emerge, the future of cable harness design will undoubtedly be shaped by the synergy between smart technology and engineering finesse.

Impact of Increased Automation on Cable Harness Manufacturing Processes

The impact of increased automation on cable harness manufacturing processes is profound and multifaceted. As industries increasingly adopt automation technologies, the traditional methods of cable harness production are evolving to meet new demands for efficiency and precision.

Automated systems now enable manufacturers to streamline assembly lines, resulting in reduced labor costs and shorter production times. Techniques such as robotic assembly and automated testing are becoming standard, allowing for higher accuracy in wiring configurations and a significant decrease in human error.

Moreover, automation facilitates the integration of advanced technologies such as machine learning and artificial intelligence into the manufacturing process. These innovations allow for real-time monitoring and adjustments during production, ensuring that any defects or inconsistencies are addressed swiftly. As a result, manufacturers can improve product quality while also enhancing their capacity to customize cable harnesses to fit specific client requirements.

This shift towards automated processes not only optimizes production efficiency but also positions companies to better respond to the rapidly changing technological landscape of the cable harness sector.

Sustainability Trends Driving Eco-Friendly Materials in Cable Harness Production

The trend toward sustainability in cable harness production is increasingly shaped by the need for eco-friendly materials and renewable energy practices. As the industry grapples with environmental challenges, manufacturers are adopting innovative approaches that focus on using sustainable materials, such as bioplastics and recycled components, which not only minimize ecological impact but also address the rising demand for greener solutions in various sectors, particularly in automotive and renewable energy applications.

In Europe, the wire and cable market is set to experience significant growth, projected to reach USD 56.26 billion by 2033, driven in part by a growing emphasis on sustainable technology. This growth indicates a larger trend of integrating sustainability into production processes, which includes the use of sustainable technologies that improve efficiency and reduce waste. Companies are not only looking to innovate but also to respond to consumer preferences for environmentally responsible products, further supporting market expansion in the sustainable cable harness sector.

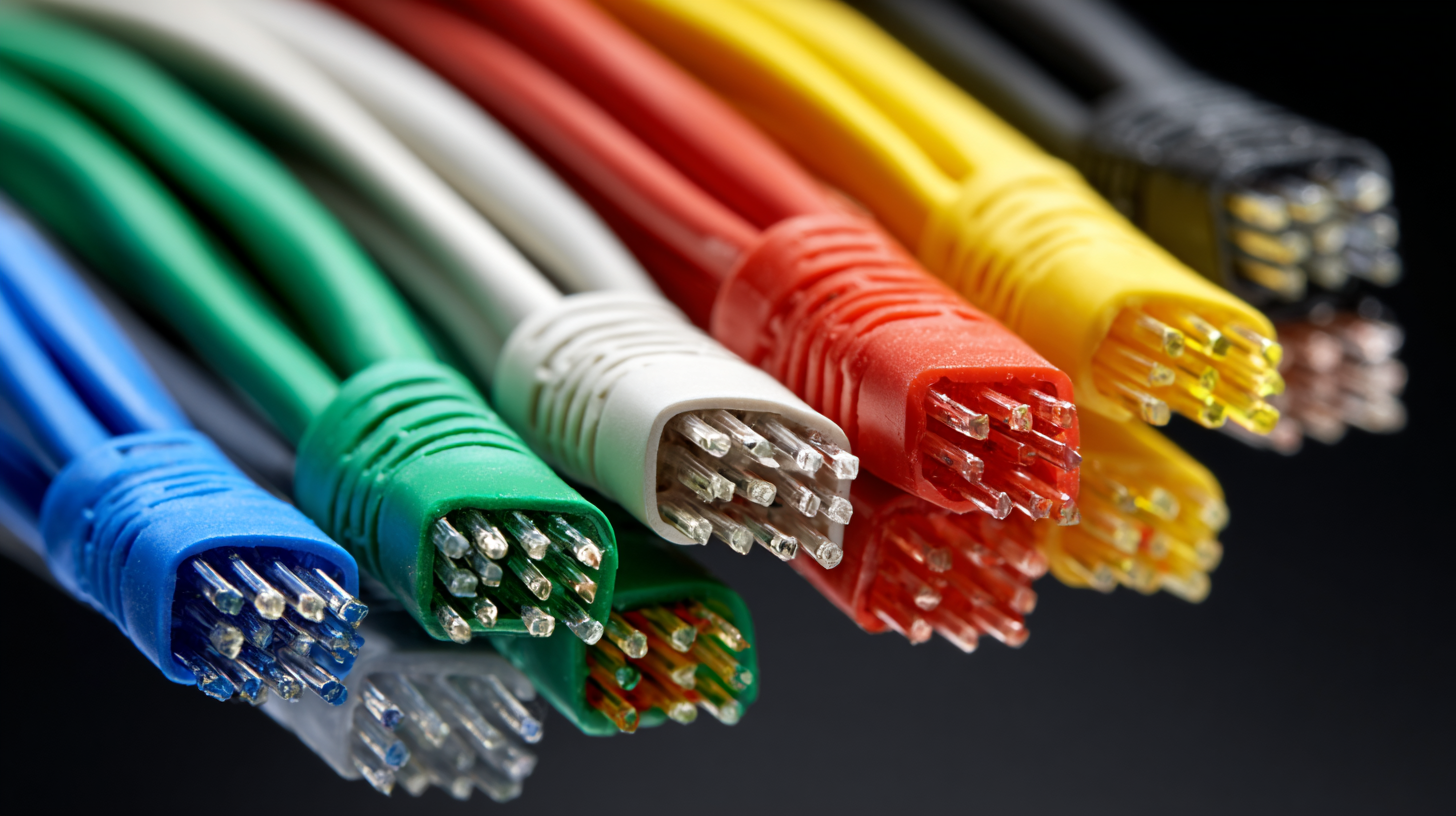

Integration of IoT Solutions in Cable Harness Systems for Enhanced Connectivity

The integration of Internet of Things (IoT) solutions into cable harness systems is revolutionizing the way industries manage connectivity and data transfer. According to a recent industry report by MarketsandMarkets, the global IoT market is expected to grow from $300 billion in 2023 to over $1 trillion by 2026, showcasing a compound annual growth rate (CAGR) of 24.9%. This explosion in IoT applications emphasizes the vital role that cable harness systems will play in facilitating seamless communication between devices. Smart cable harnesses equipped with IoT technologies not only streamline data exchange but also enhance real-time monitoring and diagnostics, which is crucial for sectors like automotive and aerospace.

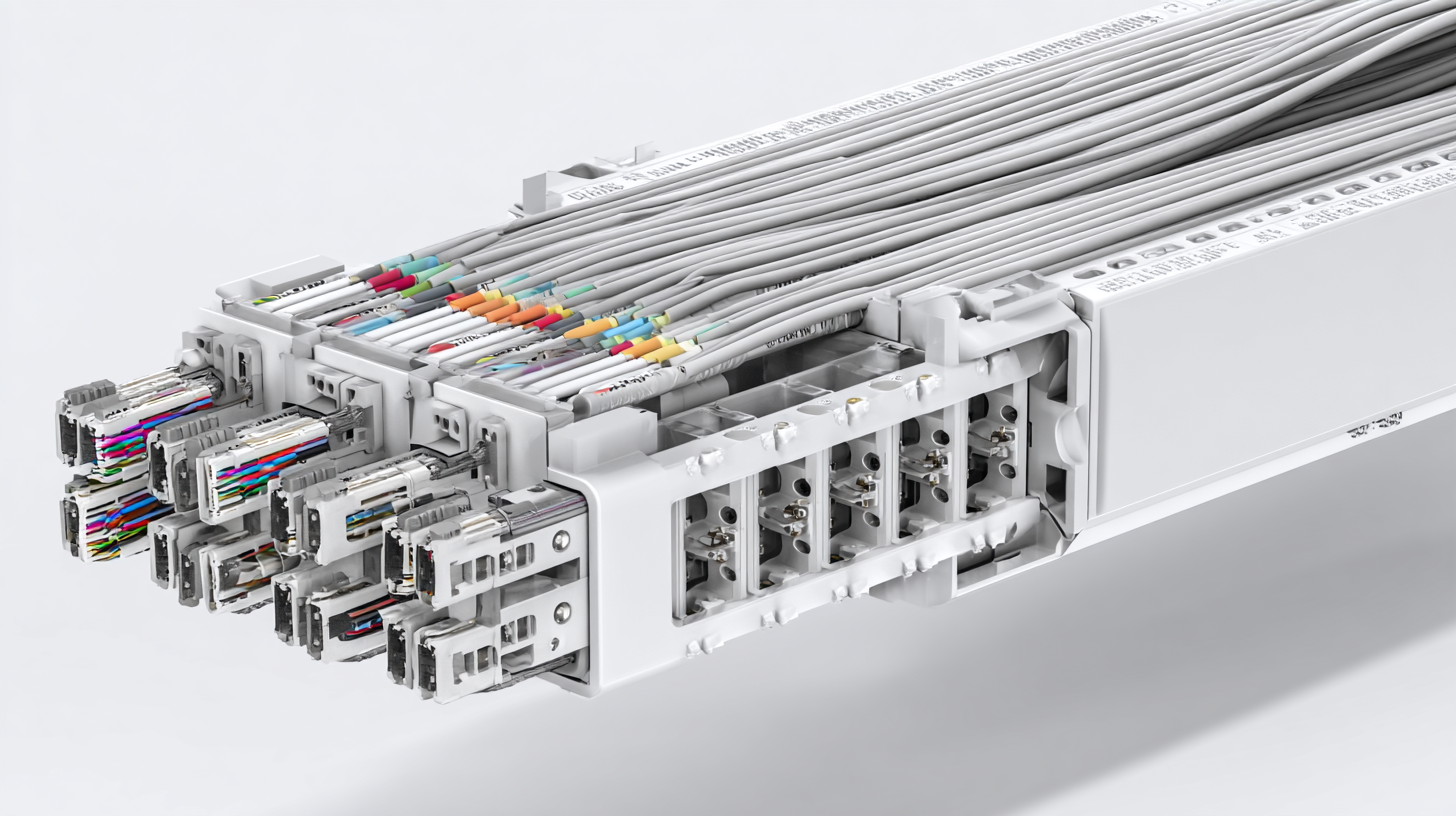

As manufacturers increasingly demand more integrated solutions, cable harness innovations are adapting to include advanced connectivity options such as wireless modules and built-in sensors. The 2025 Cable Harness Innovations report highlights that over 60% of new harness designs incorporate some form of IoT capabilities. These advancements allow for greater flexibility and scalability while addressing the challenges associated with increased data demands. Furthermore, this integration is leading to reduced installation times and enhanced operational efficiency, proving indispensable as industries move towards more automated and interconnected systems.

2025 Top Cable Harness Innovations and Trends You Need to Know - Integration of IoT Solutions in Cable Harness Systems for Enhanced Connectivity

| Innovation/Trend | Description | Impact on Connectivity | Expected Adoption Year |

|---|---|---|---|

| Smart Connectors | Connectors that incorporate sensors for real-time data monitoring. | Enables predictive maintenance and enhanced user feedback. | 2025 |

| AI-Powered Design Tools | Software tools that utilize AI for optimized cable harness design. | Increases efficiency and reduces errors in design stages. | 2025 |

| Wireless Cable Harness Systems | Harness systems that utilize wireless technology for data transmission. | Reduces cable bulk and increases design flexibility. | 2025 |

| Sustainable Materials | Use of eco-friendly materials in cable harness manufacturing. | Promotes environmental responsibility and sustainability. | 2025 |

| Modular Cable Systems | Systems that allow for easy reconfiguration and upgrades. | Enhances adaptability in fast-changing tech landscapes. | 2025 |

Data-Driven Innovations in Cable Harness Testing and Quality Assurance Methods

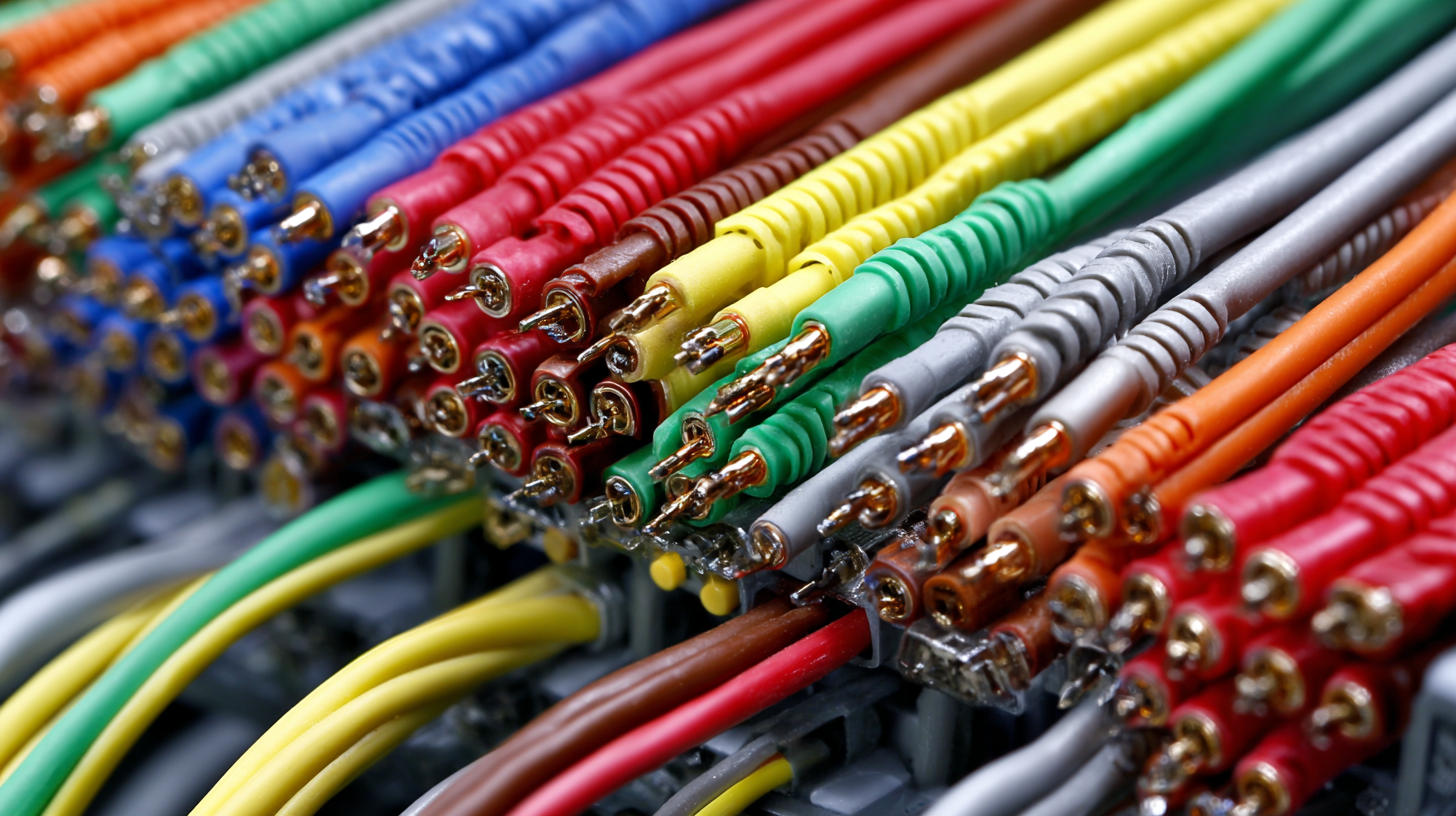

In recent years, the cable harness industry has seen remarkable advancements driven by data analytics and innovative testing methodologies. The integration of real-time data tracking into cable harness testing allows manufacturers to monitor performance metrics more accurately and reduce the occurrence of defects. With the rise of smart manufacturing, harnesses are now equipped with sensors that provide continuous feedback during production, ensuring that any deviations from quality standards can be promptly addressed. This data-driven approach not only enhances product reliability but also streamlines the entire manufacturing process.

Quality assurance methods have also evolved significantly, with the application of machine learning algorithms for predictive analysis. These tools are capable of identifying potential failure modes before they occur, enabling proactive measures to be implemented in the design and testing phases. Moreover, automated testing systems powered by artificial intelligence can conduct high-throughput testing, dramatically increasing the efficiency of quality control processes. As these innovations continue to unfold, businesses can expect not only improved safety and performance of cable harnesses but also substantial cost savings and a competitive edge in the market.

2025 Cable Harness Testing and Quality Assurance Trends

Related Posts

-

Understanding the Essentials of Cable Harness: A Comprehensive Guide for Beginners

-

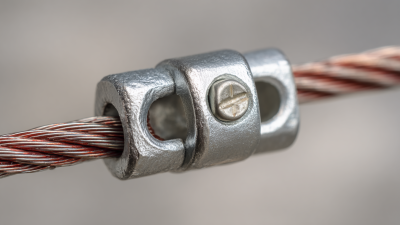

Understanding the Importance of Cable Clamps in Modern Electrical Installations

-

The Ultimate Guide to Understanding Control Wires: Applications, Types, and Best Practices

-

Top 10 Cable Wire Cable Types for Your Home and Business Needs

-

Understanding the Role of Wire Cable Connectors in Modern Technology Systems