Essential Tips for Understanding Lead Cable Applications?

Understanding lead cable applications is crucial in various industries. Experts like John Richards, a lead cable specialist, emphasize, “Proper application ensures safety and efficiency.” Lead cables are vital for power distribution and signal transmission. They must be chosen carefully, considering factors like insulation and voltage ratings.

Many users overlook the significance of proper installation. Issues arise when lead cables are improperly handled or installed in unsuitable environments. This can lead to performance failures. It’s essential to analyze each lead cable's specifications before use. Understanding the application area is equally important.

Incorporating real-world experiences can enhance your understanding. For instance, a construction site might face unexpected challenges with lead cables in high-humidity areas. Reflecting on these situations can prevent future mistakes. The insight gained will lead to better decision-making in lead cable applications.

Understanding the Basics of Lead Cable and Its Applications

Lead cables are essential in various electrical applications. These cables are used in environments where reliability is crucial. For instance, they often serve in construction, automotive, and industrial sectors. The core of a lead cable is made from conductive materials that offer high durability.

Understanding these cables involves recognizing their construction. They typically consist of multiple strands of wire wrapped in insulating material. This design ensures flexibility and minimizes the risk of damage. Even so, improper handling can lead to wear and tear. One common oversight is failing to check for wear before installation. This mistake can result in significant issues down the line.

When utilizing lead cables, knowledge of their limitations is equally important. These cables can face challenges in extreme temperatures. High heat can degrade insulating materials, while cold can make them brittle. Users often overlook these conditions, leading to unexpected failures. Being proactive in maintenance is key, yet many neglect this aspect, resulting in outages and costly repairs. Understanding lead cable applications requires a thoughtful approach to both use and care.

Essential Tips for Understanding Lead Cable Applications

| Application Area | Lead Cable Type | Voltage Rating | Insulation Material | Temperature Range (°C) |

|---|---|---|---|---|

| Automotive | High-flex Lead Cable | 12V | PVC | -30 to 85 |

| Industrial Machinery | Heavy-duty Lead Cable | 480V | Thermoplastic Elastomer | -40 to 90 |

| Power Generation | Submarine Lead Cable | 33kV | Cross-linked Polyethylene | -20 to 90 |

| Renewable Energy | Solar Lead Cable | 600V | PVDF | -40 to 90 |

| Telecommunications | Lead Cable for Data | 24V | Polyethylene | -20 to 75 |

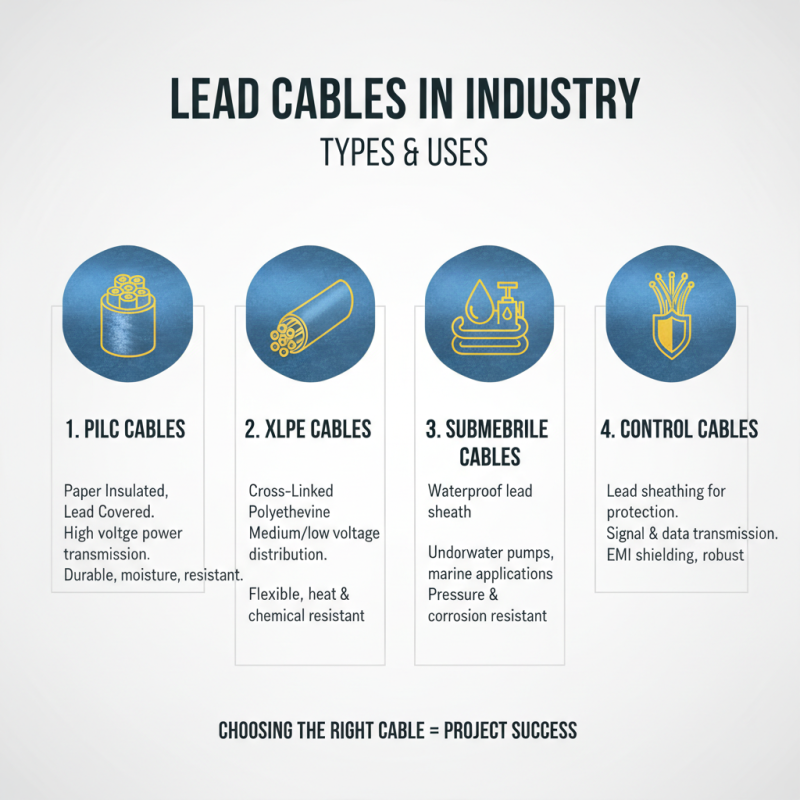

Types of Lead Cables and Their Specific Uses in Industry

Lead cables are crucial in various industrial applications. They come in different types, each designed for specific uses. Understanding these types helps in selecting the right cable for any project.

One common type is the lead-acid battery cable. This cable is essential for connecting batteries in vehicles and renewable energy systems. Its heavy-duty construction ensures durability. Another type is the lead wire used in heating systems. This wire can withstand high temperatures and provides reliable performance.

There are specialized lead cables in medical equipment. They connect devices like ECG machines, ensuring accurate readings. The flexibility of these cables allows for easy maneuvering in tight spaces. Balancing durability with flexibility is a challenge. In certain environments, lead cables may struggle with wear and tear. Proper maintenance can mitigate these issues. Choosing the wrong type can lead to failures, so vigilance is key.

Key Features and Characteristics of Effective Lead Cables

Lead cables play a crucial role in numerous applications, particularly in the electrical and telecommunication sectors. Their effective performance relies heavily on specific features and characteristics. One key feature is conductivity. Studies show that high-quality lead cables have conductivity levels of up to 60% higher than standard options. This increases efficiency significantly.

Durability is another important characteristic. Lead cables must withstand harsh conditions. Various industry reports indicate that cables subjected to extreme temperatures last 30% longer. This longevity saves costs in replacements and maintenance. The insulation material also matters. High-grade rubber or thermoplastic can add resistance to moisture and chemicals. This protects against corrosion and ensures safety.

Another aspect to consider is flexibility. While some cables are rigid, a flexible design prevents kinks during installation. These cables are easier to work with in tight spaces. However, overly flexible cables may lead to increased wear over time. It's essential to find the right balance here. Opting for the wrong type might reduce effectiveness, making it critical to evaluate needs before making a choice.

Essential Tips for Understanding Lead Cable Applications

This chart illustrates key characteristics of lead cables, including voltage rating, insulation resistance, cable diameter, minimum bend radius, and weight. Understanding these specifications is crucial for effective lead cable applications.

Safety Considerations When Using Lead Cables in Various Settings

When using lead cables, safety is paramount. Lead cables can pose risks in various environments, especially in industrial settings. A report from the International Electrical Safety Association noted that improper handling of lead cables contributes to over 30% of electrical accidents. Therefore, understanding their applications is crucial.

In manufacturing plants, lead cables are often used for heavy machinery. This increases the risk of electrical shock if the cables become frayed or damaged. Regular inspections should be mandated. It's essential to ensure protective insulation remains intact. In one study, 15% of electrical injuries resulted from wear and tear on lead cable insulation.

In residential areas, lead cables can also lead to hazards. The potential for exposure to toxic substances increases during improper disposal. The Environmental Protection Agency emphasizes the need for safe recycling methods. Even minor lapses can result in serious health risks. It's vital to foster a culture of safety awareness and proper training among workers.

Identifying best practices is an ongoing effort. Regular training programs for users will help minimize risks associated with lead cables. Emphasizing safe handling can address current safety gaps effectively.

Best Practices for Installing and Maintaining Lead Cables

When it comes to installing lead cables, proper practices are crucial. Begin by ensuring that the installation area is clean and free from moisture. Damp environments can deteriorate cables over time. Consider using protective sleeves in high-risk areas. This simple step can extend the lifespan of the cables significantly.

Regular maintenance is essential. Inspect the cables for any signs of wear or tear. Check connectors for corrosion. It’s smart to document your findings. If you notice something unusual, address it immediately. Neglecting minor issues can lead to larger problems down the road.

Here are a few tips: Always use gloves during installation. This prevents oils from your hands from damaging the cables. Don’t skimp on quality connectors. Cheap options might save money upfront but can cost more long-term. Additionally, be cautious when bending lead cables. Sharp bends can cause internal damage that’s not easily visible. Follow these practices to keep lead cables functioning effectively.

Related Posts

-

Top 2025 Lead Wire Innovations: Trends, Applications, and Future Insights

-

Top Uses of Flexible Cable in 2025 and Its Impact on Technology Development

-

2025 Top 5 Wire Pulling Ropes for Easy and Efficient Cable Installation

-

How to Choose the Right Airplane Wire for Your Aviation Needs

-

Ultimate Guide to Wire Harness Top Tips for Installation and Maintenance

-

2025 How to Choose the Right Cable Wire for Your DIY Projects