10 Essential Tips for Choosing the Right Cable Clamp for Your Project

In the realm of construction and engineering, selecting the appropriate cable clamp can significantly impact the overall efficacy and safety of any project. As Bob Anderson, an industry expert with over 20 years of experience in electrical installations, aptly puts it, "The right cable clamp not only secures the cables but also ensures longevity and functionality in the system." Understanding the various types and specifications of cable clamps is crucial for professionals seeking to optimize their work processes and avoid potential pitfalls.

As technology advances, the options available for cable clamps have diversified, making it imperative for project managers and engineers to stay informed about the latest developments. This guide aims to provide essential tips for choosing the right cable clamp tailored to your specific needs. From considering the materials and load requirements to understanding the environmental factors that may affect installation, each decision can determine the success of your project.

Ultimately, the goal is to equip you with the knowledge necessary to make an informed choice, ensuring that your installation remains secure and efficient throughout its lifespan. With the right guidance, selecting a cable clamp can transform from a daunting task into a straightforward process, setting the foundation for a successful project.

Understanding the Different Types of Cable Clamps Available

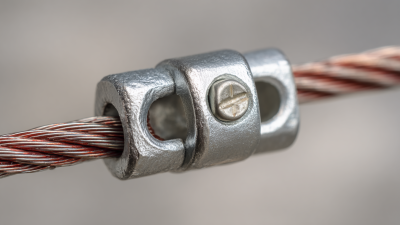

When selecting the right cable clamp for your project, it's essential to understand the various types available and their specific applications. Cable clamps come in multiple designs, including screw-type clamps, loop clamps, and snap-on clamps, each suited for different wire sizes, installation environments, and load requirements. Screw-type clamps, for instance, provide a secure grip and are versatile for various indoor and outdoor uses, while loop clamps are ideal for applications requiring minimal vibration.

One of the key tips is to consider the material of the cable clamp. Common materials include plastic, metal, and rubber, each offering different levels of durability and flexibility. If your project involves exposure to harsh conditions, opt for materials that are resistant to corrosion and wear. Additionally, ensure the clamp size matches the cable diameter to achieve optimal performance—clamps that are too tight can damage the cable, while those that are too loose might not hold securely.

Further, when installing cable clamps, ensure they are spaced correctly to avoid stress on the cable. A good rule of thumb is to allow for enough slack for thermal expansion and contraction, especially in outdoor installations. Proper installation not only ensures safety but also enhances the longevity of the cables. By understanding the different types of cable clamps and following these essential tips, you can make an informed decision that best suits your project’s requirements.

Evaluating Cable Clamp Materials for Durability and Performance

When selecting the right cable clamp for your project, the material of the clamp plays a crucial role in ensuring both durability and performance. The most commonly used materials for cable clamps include stainless steel, nylon, and rubber. According to a 2023 industry report from the International Electrical and Electronics Engineers (IEEE), stainless steel is favored for its resistance to corrosion and mechanical stress, making it ideal for outdoor applications or environments with high humidity. In fact, stainless steel clamps can last up to five times longer than their plastic counterparts in rugged conditions, which significantly reduces replacement costs over time.

Nylon cable clamps, while not as durable as stainless steel, offer excellent insulative properties, which can be beneficial in applications where electrical conductivity needs to be minimized. Furthermore, a study conducted by the Materials Research Society in 2022 indicated that nylon clamps can withstand temperatures ranging from -40°C to 120°C, making them suitable for a variety of environments. The flexibility of a nylon clamp also allows for a snug fit around cables, reducing the risk of wear and tear. This flexibility, combined with their lightweight design, makes nylon clamps a popular choice in the automotive and electronics industries.

Rubber clamps also provide unique advantages, particularly in settings where vibration dampening is essential. Research has shown that rubber can absorb shock and vibration up to 50% more effectively than hard materials. For projects involving moving parts or exposed wiring, rubber clamps can enhance both safety and longevity, as they prevent damaging cable movement while maintaining grip. By evaluating these materials against the demands of your specific project, you can ensure optimal performance and durability of your cable management solutions.

Considerations for Cable Size and Type in Clamp Selection

When selecting a cable clamp for your project, understanding the specific cable size and type is crucial for ensuring the clamp’s effectiveness and durability. According to industry standards, the proper clamp should match the diameter of the cable being used to prevent slippage or damage. Misalignment between clamp size and cable size can lead to mechanical failures. For instance, a study published by the International Wire and Cable Symposium notes that improper cable clamping can account for nearly 15% of system failures in various applications, making accurate measurements and selections imperative.

Additionally, the material of the cable, whether it is copper, aluminum, or fiber optic, plays a significant role in clamp selection. Each cable type has distinct characteristics and requires clamps that can safely handle the specific thermal and mechanical properties associated with them. Research from the Electrical and Electronics Engineers Association suggests that choosing the right clamp material, such as stainless steel or plastic, can enhance performance and longevity, with stainless steel offering better resistance to corrosion and mechanical stress in outdoor environments. Therefore, understanding the interplay between cable type and clamp specifications is essential for optimizing project outcomes.

Assessing the Environment: Indoor vs. Outdoor Cable Clamp Choices

When selecting cable clamps for your project, the environment in which they will be used plays a crucial role in determining the right choice. Indoor installations typically require different materials and specifications compared to outdoor settings. Indoor cables often benefit from plastic or rubber clamps that offer sufficient grip to secure cables without risking damage or wear. These clamps can be simpler to install and provide a clean aesthetic for indoor environments, where visibility and organization are important.

On the other hand, outdoor cable clamps must be resilient to various weather conditions, including moisture, UV rays, and temperature fluctuations. Metal clamps, often galvanized or coated to resist corrosion, may be the best option for outdoor use, ensuring durability and longevity under harsh elements. Furthermore, the design of the clamp should facilitate drainage and prevent moisture buildup, which could compromise electrical connections. By carefully assessing the specific environmental conditions and the type of cables being used, you can select the most suitable cable clamp that ensures safety and efficiency in your project.

Installation and Maintenance Tips for Optimal Cable Clamp Functionality

When installing cable clamps, proper placement and tensioning are critical to ensuring their effectiveness. Start by selecting locations that not only provide ample support but also consider the movement and flexibility of the cables. Over-tightening can cause damage to the wiring, resulting in potential electrical failures, while under-tightening may lead to slippage. It’s advisable to use a torque wrench to achieve the correct tension specified for your cable size, promoting both safety and longevity.

Regular maintenance of cable clamps is essential for sustained functionality. Periodically inspect the clamps for corrosion, deformation, or wear, especially in environments exposed to moisture or varying temperatures. Cleaning the clamps and surrounding areas of debris build-up can prevent deterioration and ensure a secure hold. Furthermore, checking the positioning and tension regularly helps to preemptively address any issues before they escalate, contributing to the overall reliability of your electrical installation.

10 Essential Tips for Choosing the Right Cable Clamp for Your Project

| Tip Number | Tip Description | Material Type | Recommended Usage |

|---|---|---|---|

| 1 | Determine the appropriate size for your cables. | Plastic | Indoor use, lightweight applications. |

| 2 | Choose corrosion-resistant materials for outdoor use. | Stainless Steel | Outdoor installations. |

| 3 | Check the load capacity of the clamp. | Aluminum | Heavy-duty applications. |

| 4 | Select a design that matches your project’s aesthetic. | Coated Steel | Visible installations. |

| 5 | Ensure easy installation and access for future maintenance. | Nylon | Easily adjustable applications. |

| 6 | Consider the environmental conditions where the clamp will be used. | Rubber | Vibration dampening applications. |

| 7 | Look for clamps with built-in strain relief. | Flexible Plastic | Protecting cable integrity. |

| 8 | Research the installation requirements for specific clamps. | Galvanized Steel | Long-term installations. |

| 9 | Ensure compatibility with the cable insulation. | Composite | High-performance applications. |

| 10 | Account for future expansion needs when selecting clamps. | Adjustable Metal | Scalable installations. |

Related Posts

-

Understanding the Importance of Cable Clamps in Modern Electrical Installations

-

How to Choose the Right Cable Clamp for Your Project Needs

-

Top 10 Power Wire Types You Need for Your Electrical Projects in 2023

-

Top 10 Best Control Wire Types for Optimal Performance and Durability

-

What is a Wire Cable Connector? Understanding Types and Applications

-

2025 Top 5 Wire Pulling Ropes for Easy and Efficient Cable Installation