How to Properly Use Power Wire in Your Electrical Projects?

When embarking on electrical projects, understanding how to properly use power wire is crucial. Power wires are the lifeline of any electrical system, delivering energy from one point to another. They connect various components and ensure they function correctly. Choosing the right power wire can make a significant difference in both safety and efficiency.

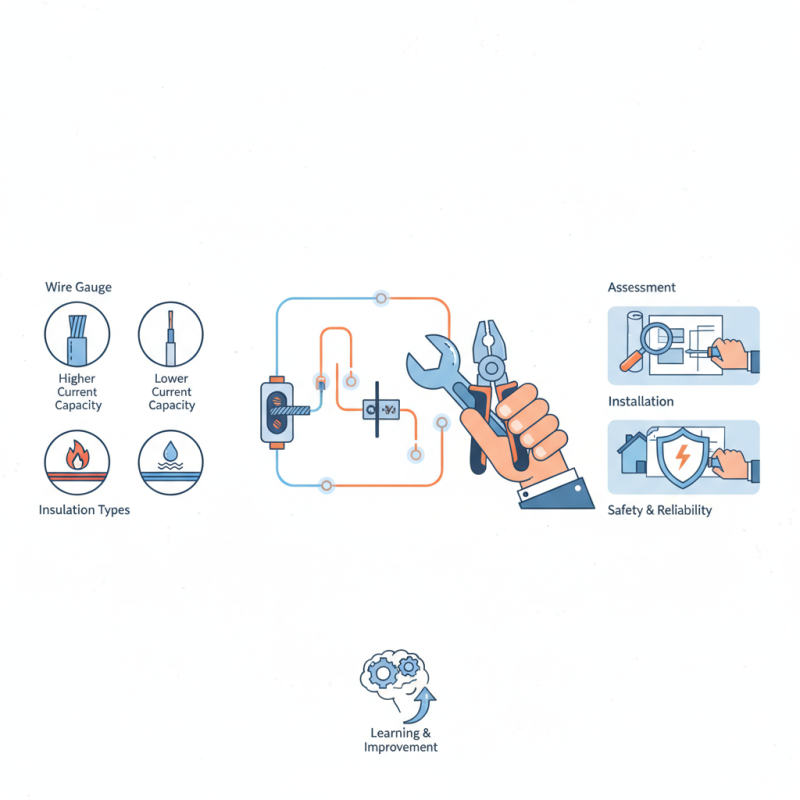

Many beginners overlook the importance of wire gauge and insulation type. A thicker gauge can carry more current, while insulation protects against short circuits and electrical fires. It's essential to assess your project requirements carefully. Misjudgments can lead to severe risks and costly repairs.

Moreover, proper installation techniques are vital. Poor connections can lead to voltage drops and equipment failure. This highlights the need for diligence and attention to detail. Be prepared to take time and reflect on your choices. Learning from mistakes is part of the process. Using power wire correctly is not just about connecting devices; it's about ensuring long-term safety and reliability.

Understanding Power Wire Types and Ratings

When working on electrical projects, understanding power wire types and ratings is essential. Different wires serve various purposes. For instance, THHN wires are common in general wiring, but they can be less flexible. Conversely, stranded wires offer more flexibility but may not handle heavy loads well. Knowing the right type can make or break a project.

Power wire ratings are equally important. Wires are rated by their amperage capacity and voltage. A 14-gauge wire might carry up to 15 amps safely. If overloaded, it could heat up, leading to potential fire hazards. Another aspect is insulation. Some wires have better insulation for wet conditions, while others might wear quickly under UV exposure. Always consider where the wire will be used.

Reflecting on personal experiences, I’ve made mistakes by underestimating these ratings. Once, I used a low-rated wire; it melted and damaged my project. Such lessons remind us to choose wisely. The right wire can ensure safety and efficiency, while poor choices may lead to failures. Stay informed and make better selections.

Safety Precautions When Handling Power Wires

Handling power wires safely is crucial in any electrical project. The National Safety Council reports that electrical injuries account for thousands of emergencies each year. Proper precautions can significantly reduce these risks. Always wear insulated gloves and safety glasses. Keep a first aid kit nearby.

When dealing with power wires, it’s essential to disconnect the power supply. Using a multimeter can help verify that no voltage is present. According to the Electrical Safety Foundation International, 43% of electrical accidents occur when individuals assume power is off. Don't take chances; check and double-check.

Tips: Label wires clearly. Unorganized wiring can lead to confusion. Also, avoid overloading circuits. It's easy to underestimate how much power devices draw. Remember, safety comes first. If in doubt, consult a professional. Taking shortcuts can lead to dangerous mistakes. Keep safety equipment on hand. Never work alone, especially on large projects. Making assumptions is a common pitfall. Stay alert and focused on the task at hand.

Essential Tools for Working with Power Wires

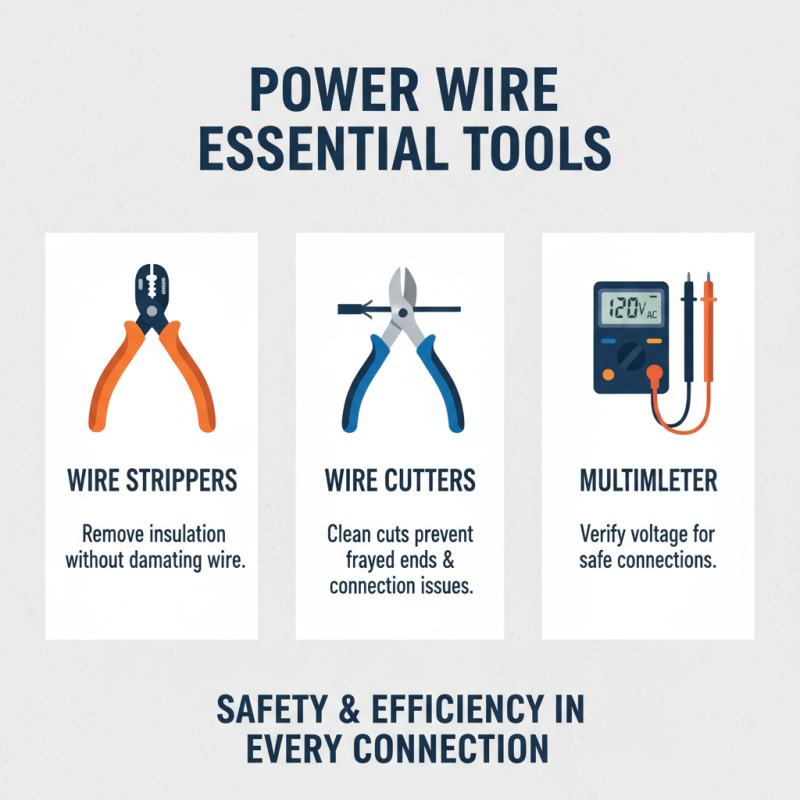

When working with power wires, having the right tools is essential for safety and efficiency. A good set of wire strippers can help remove insulation without damaging the wire. Invest in quality wire cutters as well. Dull cutters can lead to frayed ends, causing connection issues. A multimeter is indispensable; it helps ensure you’re working with the correct voltage before making any connections.

Tips for safety: always wear insulated gloves when handling live wires. Check your tools regularly. If they show signs of wear, replace them. It’s also wise to use electrical tape to secure connections and prevent shorts.

Consider the environment where you work. Overhead lights are a must for clear visibility. Clearing the workspace can prevent accidents. Remember, not all wires are the same. Different projects may require different gauges and insulation types. Always read the specifications before starting. Mistakes can lead to accidents or damage, so being detail-oriented is crucial. Be mindful of your limits and don’t hesitate to consult a professional when in doubt.

Techniques for Properly Connecting Power Wires

Connecting power wires can seem straightforward, but proper techniques are crucial for safety and functionality. Begin by stripping the insulation off the wire. Use a suitable wire stripper and take care not to damage the copper underneath. A clean cut ensures better conductivity.

When connecting wires, twist-on wire connectors are a reliable choice. Make sure to match colors when possible. For example, black to black, white to white. This simplicity can reduce errors. However, it is essential to double-check connections before applying power. Mistakes can lead to shorts or failures.

Grounding is a critical step often overlooked. Connecting to a ground wire protects against electrical shocks. Make sure the ground connection is secure. If you are uncertain about your work, don’t hesitate to consult an expert. This reflection on your skills can save you from serious issues down the line. Each project is a learning opportunity.

How to Properly Use Power Wire in Your Electrical Projects?

| Technique | Description | Safety Tips | Common Mistakes |

|---|---|---|---|

| Stripping Wires | Use a wire stripper to remove insulation without damaging the conductor. | Always cut off power before working on any electrical project. | Not stripping enough insulation can lead to poor connections. |

| Twisting Wires | Twist wires together tightly to ensure a secure connection. | Use insulated tools to avoid short-circuiting. | Loose connections can lead to overheating. |

| Using Connectors | Utilize proper connectors (like wire nuts) for secure and safe connections. | Select connectors rated for the wire gauge and application. | Using the wrong connector can lead to failure. |

| Insulating Connections | Wrap connections in electrical tape or use heat shrink tubing for insulation. | Ensure the area is dry before applying insulation materials. | Neglecting insulation can cause short circuits. |

| Testing Connections | Use a multimeter to verify that connections are secure and functioning. | Ensure all power is off before testing. | Failing to test can result in undetected issues. |

Common Mistakes to Avoid in Electrical Wiring Projects

When tackling electrical wiring projects, one of the most common mistakes is improper wire sizing. Using wires that are either too thick or too thin can lead to overheating and potential hazards. It's crucial to refer to local building codes and electrical standards. These resources provide valuable guidelines on which wire gauge to choose for your specific needs. Don’t simply rely on assumptions; measure and calculate your load requirements accurately.

Another frequent error is neglecting to secure connections properly. Loose connections can result in arcing or intermittent power loss. This issue often goes unnoticed until severe damage occurs. Always use appropriate connectors and ensure they are tightly fastened. Taking the time to double-check your work can save you from costly repairs later on.

Lastly, many overlook the importance of planning and layout. Rushing through the initial stages often leads to errors that are hard to fix. Sketching out your project helps visualize the wiring path and identify potential obstacles. It's easy to skip this step, but doing so may lead to wasted time and resources later. A careful approach can help avoid many pitfalls in your electrical projects.

Related Posts

-

Top 10 Power Wire Types You Need for Your Electrical Projects in 2023

-

10 Essential Tips for Choosing the Right Electrical Cable for Your Needs?

-

Best Electrical Wire Types for Your Projects?

-

Top 10 Must-Know Facts About Cable Harnesses for Your Next Project

-

Top 10 Cable Connectors You Need for Your Electronics Projects

-

How to Use Wire Clips for Organizing Cables and Enhancing Safety at Home