Why Are Cable Ends Important for Electrical Connections?

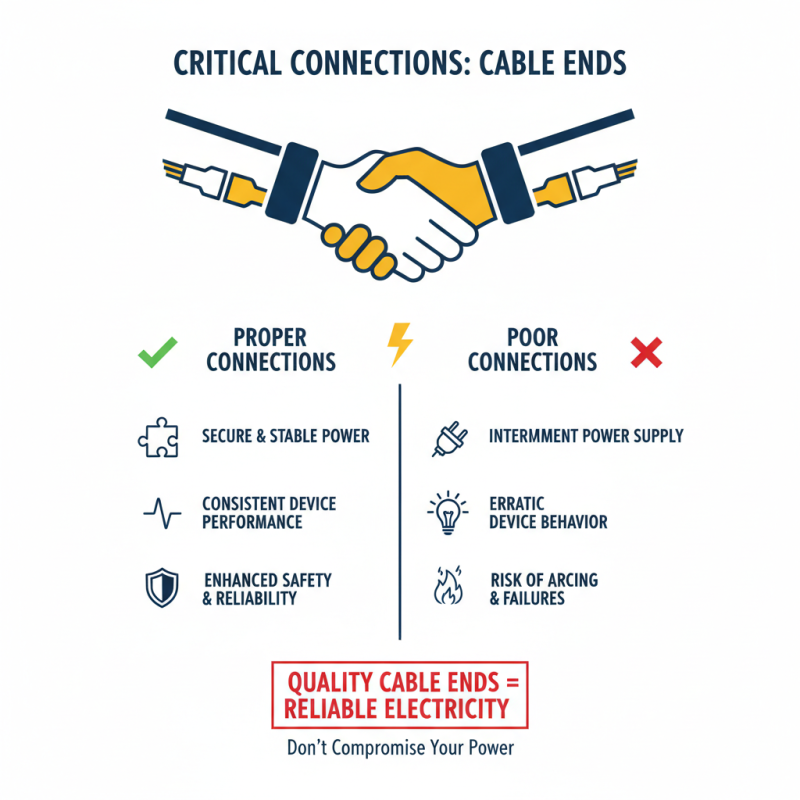

Cable ends play a crucial role in electrical connections. They serve as the interface between the wires and the devices they power. Properly designed cable ends ensure a secure connection, which is vital for safety and efficiency.

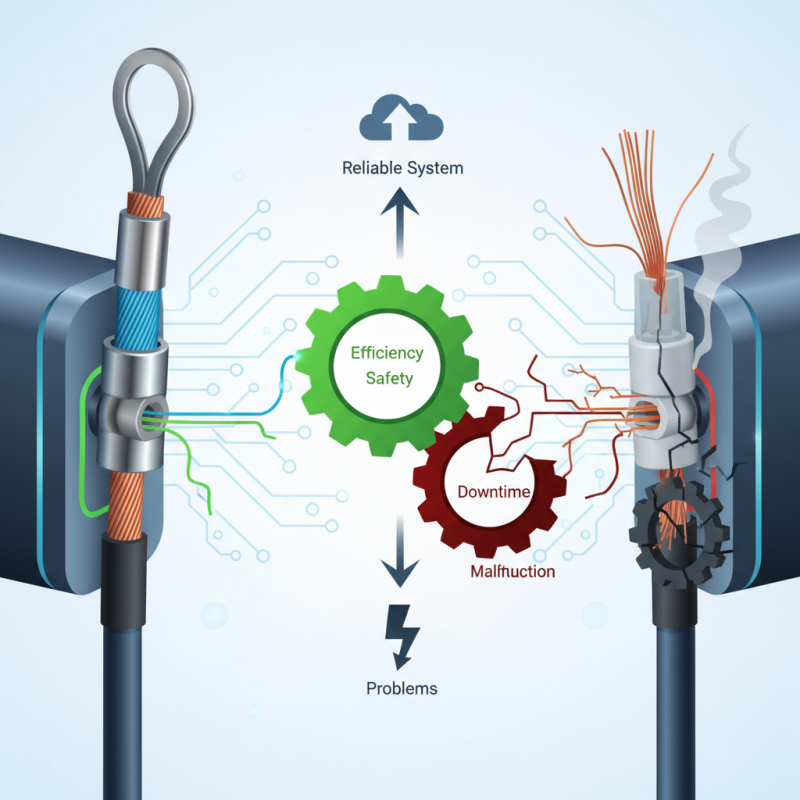

In many applications, the quality of cable ends directly impacts the performance of the entire system. Poorly made cable ends can lead to short circuits or intermittent connections. These issues often result in unplanned downtime or malfunctioning equipment. This raises questions about the importance of using high-quality materials and precise manufacturing processes.

While cable ends may seem minor, their influence is significant. Users often overlook them, focusing instead on larger components. However, neglecting the details of cable ends can lead to bigger problems. Consider investing time and resources to ensure these connections are reliable. After all, the success of an electrical system often depends on the small, seemingly unimportant parts.

Importance of Cable Ends in Electrical Connectivity

Cable ends play a crucial role in electrical connectivity. They act as the final link between the power source and the device. A strong connection at this point ensures efficient energy transfer. According to industry reports, faulty cable ends can cause up to 30% of electrical failures in various systems. This highlights their importance in maintaining reliability in electrical setups.

Properly terminated cable ends minimize resistance and heat build-up. This can improve the overall performance of electrical installations. Moreover, according to a study by the Electrical Safety Foundation International, nearly 60% of electrical fires stem from poor connections. This statistic underscores the need for attention to detail in cable end preparation.

Tips: Always inspect cable ends for any signs of wear or corrosion. Use appropriate tools for termination to ensure a secure fit. Remember, a small oversight in the cable end can lead to significant consequences. Check connections regularly to prevent unexpected failures. Regular maintenance can save costs in the long run.

Importance of Cable Ends in Electrical Connectivity

In electrical connectivity, the type and quality of cable ends play a crucial role in ensuring reliable electrical connections. The chart above illustrates the percentage of different cable types used in various applications, highlighting the prevalence of copper and aluminum as the most commonly used materials.

Types of Cable Ends and Their Applications in Electrical Systems

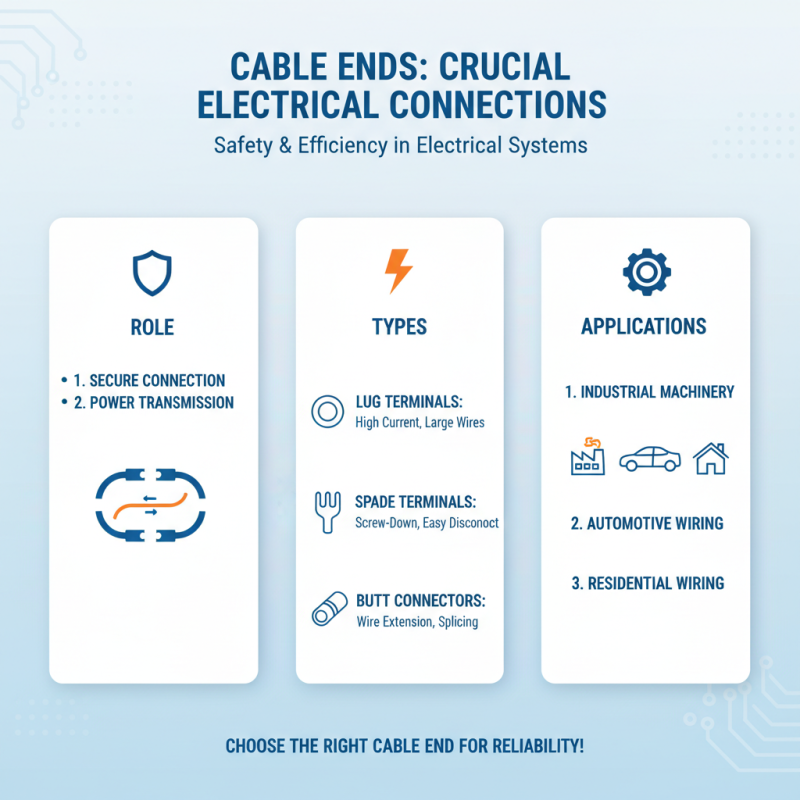

Cable ends play a crucial role in electrical connections. Various types of cable ends serve specific functions in electrical systems. Different applications require different cable ends to ensure safety and efficiency.

One common type is the lug. It provides a solid connection for larger cables. Lugs are often used in heavy machinery. They require careful installation, as improper attachment can lead to failures. Another type is the connector. Connectors are versatile and often used in household wiring. They allow for easy connection and disconnection. However, using the wrong connector can lead to poor performance.

Plugs and sockets are also vital. They make temporary connections easy for tools and appliances. A good plug should fit snugly. Loose connections can cause sparks or overheating. Understanding the right cable ends and their applications can prevent accidents. It's essential to educate oneself and ensure proper usage.

Impact of Poor Cable End Connections on Electrical Performance

Cable ends play a crucial role in electrical connections. Poor quality or improperly attached cable ends can lead to significant issues. For instance, a loose connection may cause intermittent power supplies. This can create erratic performance in devices that rely on stable electricity.

The impact of bad cable ends can manifest in various ways. Overheating is a common problem. When connections aren't secure, electrical resistance increases, creating heat. This can damage surrounding materials. Sometimes, sparks may occur, indicating severe connection issues. Visual inspection often reveals frayed or damaged cables, but not always. Many overlook subtle signs of wear until it's too late.

Maintaining cable integrity is essential for safety and efficiency. Relying solely on visual checks can be misleading. Regular testing and proper installation procedures can reduce the risks associated with poor connections. Understanding the basics of cable ends can save time and potential hazards in the long run.

Industry Standards for Cable End Quality and Safety Regulations

Cable ends play a crucial role in electrical connections. Their quality directly impacts safety and performance. Industry standards dictate how these cable ends should be constructed. Quality ensures reliable connections. Users may overlook this aspect. Weak cable ends can lead to accidents. Inadequate connections might create voltage drops or failures.

Regulations emphasize proper insulation and material selection. The use of subpar materials can pose risks. Depending on application, cable ends must withstand environmental factors. High humidity or extreme temperatures can degrade performance. Each connection should meet specific safety standards. This includes testing for durability and conductivity.

Often, manufacturers face challenges in adhering to these standards. Some may cut corners during production. This compromises safety. Consumers need to be vigilant. Small details, like a frayed wire, can lead to significant issues. Regular inspections and adherence to regulations are essential. Quality control is not just a checkbox; it’s a necessity.

Best Practices for Selecting and Installing Cable Ends in Projects

Choosing the right cable ends is crucial for projects, impacting both safety and performance. The first step is to assess the project's requirements. This includes factors like voltage levels and environmental conditions. Understanding these will guide your selection process.

When installing cable ends, meticulous attention is necessary. Ensure that cables are stripped correctly. Too much stripped wire can lead to shorts. On the other hand, too little can result in weak connections. This balance is essential for durability and efficiency.

Tips: Always select cable ends that match the wire gauge. Mismatched sizes can result in poor connections. Additionally, consider using heat shrink tubing for extra protection. Lastly, don't overlook the importance of regular inspections. Over time, wear and tear can render connections faulty. Taking time to check cable ends can prevent bigger issues down the line.

Related Posts

-

Top 10 Cable Ends You Need to Know for Better Connections and Performance

-

Understanding the Essentials of Cable Harness: A Comprehensive Guide for Beginners

-

Top 10 Cable Wire Cable Types for Your Home and Business Needs

-

How to Choose the Right Wire Cable for Your Electrical Projects

-

Top 10 Cable Fittings You Need to Know About?

-

2026 Best Cable Solutions for All Your Connectivity Needs?