Understanding the Importance of Cable Clamps in Modern Electrical Installations

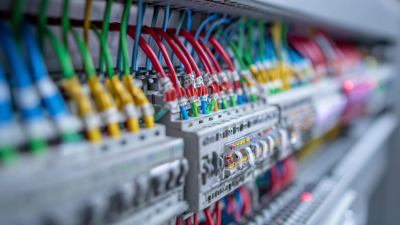

In modern electrical installations, the significance of cable clamps cannot be overstated. As a crucial component in ensuring the safety and efficiency of wiring systems, cable clamps play an essential role in securing electrical cables and preventing potential hazards such as short circuits and fire. According to a recent report by MarketsandMarkets, the global cable management market, which includes cable clamps, is projected to reach $XX billion by 2026, driven by increasing infrastructure developments and the rising adoption of automation technologies. Furthermore, the National Fire Protection Association highlights that improper cable management can account for up to 30% of electrical fire incidents, underlining the necessity for durable and reliable cable clamps in both residential and commercial settings. By understanding the importance of these devices, stakeholders can enhance the longevity and safety of electrical installations.

The Critical Role of Cable Clamps in Enhancing Electrical Safety Standards

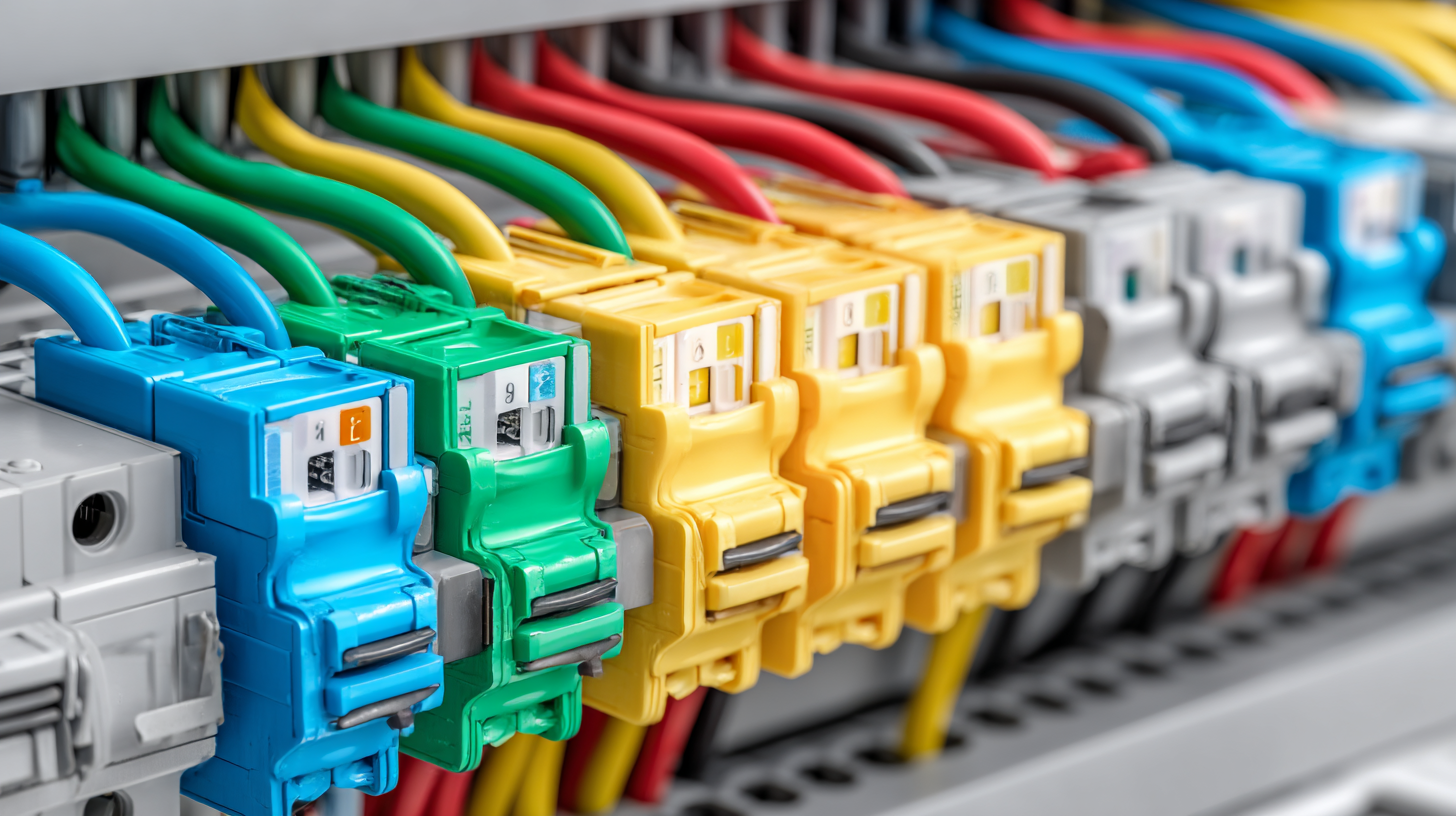

Cable clamps serve a vital role in modern electrical installations, significantly enhancing electrical safety standards. As the global market for cable cleats is projected to grow substantially, the demand for reliable cable management solutions becomes increasingly apparent. Cable clamps not only secure wiring systems but also help prevent potential hazards associated with loose or damaged cables. By ensuring that cables are firmly in place, these clamps mitigate the risk of short circuits, electrical fires, and other dangerous incidents.

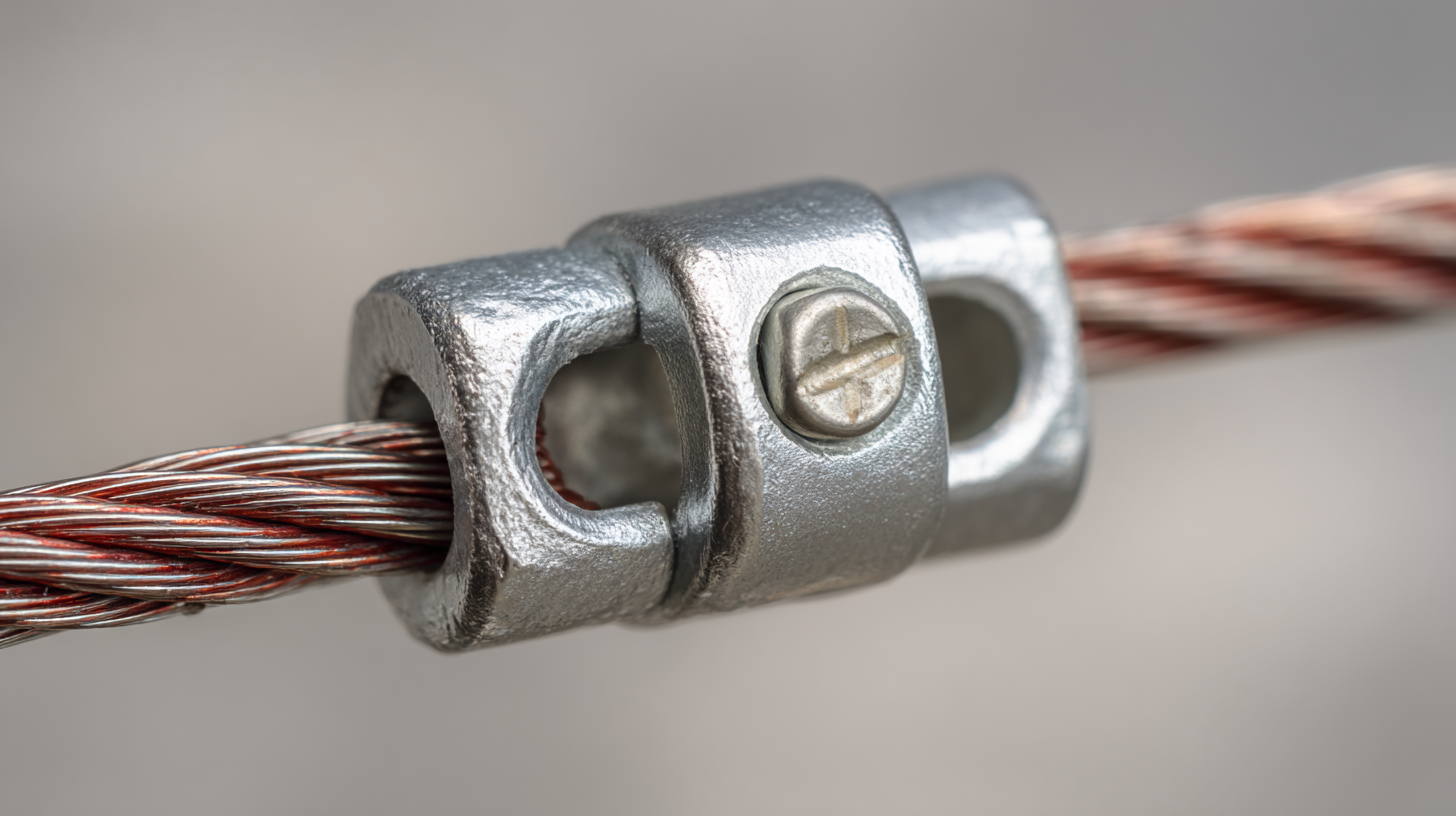

In particular, the importance of grounding is highlighted in applications such as wild turbine towers, where they are particularly susceptible to lightning strikes. Implementing an effective grounding system, alongside robust cable management through clamps, is essential in protecting against catastrophic failures. As advancements in materials and designs continue, the role of cable clamps in maintaining safe and efficient electrical installations only grows more critical, underscoring the need for adherence to updated safety standards in the industry.

Innovative Cable Clamp Designs: Ensuring Durability and Performance in Installations

Innovative cable clamp designs play a crucial role in enhancing the durability and performance of modern electrical installations. With the rapid advancement in technology, the demand for reliable and robust cable management solutions has increased. According to a report by Grand View Research, the global cable management market is expected to reach USD 25.6 billion by 2026, underscoring the critical role that high-quality cable clamps play in ensuring secure installations.

Modern cable clamps utilize advanced materials like nylon and aluminum, offering superior resistance to environmental factors such as moisture, temperature fluctuations, and mechanical stresses. A study by TechNavio has shown that the use of innovative materials can increase the lifespan of cable clamps by up to 30%. Furthermore, ergonomic designs have been developed to facilitate easier installation and maintenance, contributing to operational efficiency. As electrical systems become more complex, integrating such cutting-edge designs is essential for minimizing downtime and enhancing safety in various applications—from residential to industrial settings.

Understanding the Importance of Cable Clamps in Modern Electrical Installations

This bar chart illustrates the various factors contributing to the importance of cable clamps in electrical installations. Durability, cost efficiency, ease of installation, versatility, and performance are all crucial aspects that professionals consider when selecting suitable cable clamps for modern applications.

Statistical Analysis: Reducing Electrical Hazards through Effective Cable Management

Effective cable management is crucial for reducing electrical hazards in modern installations. Statistical analyses have shown that improper cable management contributes to a significant percentage of electrical incidents, including short circuits and fires. By ensuring that cables are organized, secured, and protected from damage, the risk of such hazards can be minimized. Implementing cable clamps is an essential strategy in this regard, as they help to maintain order and prevent the wear and tear that can lead to dangerous situations.

Moreover, the use of cable clamps can streamline maintenance practices. By securing cables in designated pathways, technicians can easily identify and access wiring for troubleshooting and repairs. This not only enhances safety but also reduces downtime caused by electrical failures. Data suggests that organizations that invest in proper cable management report lower incident rates and associated costs. In summary, prioritizing effective cable management through tools like cable clamps is key to enhancing safety and reliability in electrical environments.

Key Industry Trends: The Shift Towards Sustainable Materials in Cable Clamp Production

The growing awareness of environmental sustainability is significantly influencing the manufacturing practices within the cable clamp industry. With traditional materials, such as plastic and metal, contributing to environmental degradation, manufacturers are now prioritizing the use of sustainable materials. This shift not only reduces the ecological footprint of production but also promotes the lifecycle sustainability of the products themselves. Eco-friendly alternatives, such as bioplastics and recycled metals, are becoming more commonplace, aligning with broader industry trends aimed at reducing waste and conserving resources.

Furthermore, this paradigm shift is not merely a response to regulatory pressures; it reflects changing consumer expectations for environmentally responsible products. Companies that adopt sustainable materials in their cable clamp production can enhance their market competitiveness, attract eco-conscious customers, and bolster their brand reputation. As innovation in material science progresses, the cable clamp industry stands poised to leverage these advancements, ensuring that their products are not only effective and durable but also contribute positively to sustainable development efforts in electrical installations.

Understanding the Importance of Cable Clamps in Modern Electrical Installations - Key Industry Trends

| Material | Sustainability Rating | Cost per Unit ($) | Industry Usage (%) | Durability (Years) |

|---|---|---|---|---|

| Recycled Plastic | High | 0.50 | 30% | 5 |

| Aluminum | Medium | 1.20 | 50% | 10 |

| Steel | Low | 2.00 | 15% | 15 |

| Biodegradable Polymer | Very High | 1.00 | 5% | 4 |

| Composite Materials | High | 1.50 | 20% | 8 |

Case Studies: Real-World Impact of Cable Clamp Failures on Electrical System Efficiency

In the realm of electrical installations, cable clamps play a crucial role in ensuring system efficiency. A failure in cable clamps can lead to a range of issues, often displaying real-world consequences that dramatically impact electrical performance. For instance, in a recent case study involving a commercial building, improper cable management due to defective clamps resulted in overheating wires. This not only triggered circuit breakers but also posed significant fire risks, leading to substantial downtime and costly repairs.

Another illustrative example can be found in industrial settings, where cable clamp failures contributed to costly equipment failures in a manufacturing facility. The lack of proper cable support led to excessive movement and wear on electrical connections, resulting in unexpected shutdowns and decreased productivity. These incidents underscore the necessity of regular inspections and adherence to installation best practices, highlighting how crucial cable clamps are for maintaining the integrity and efficiency of modern electrical systems.