How to Choose the Right Wire Cable for Your Electrical Projects

When embarking on electrical projects, choosing the right wire cable is crucial, not only for the safety and efficiency of the installation but also for long-term performance. According to the latest data from the National Electrical Manufacturers Association (NEMA), electrical failures caused by improper wire selections account for over 30% of residential fire incidents each year. This alarming statistic highlights the importance of understanding the various types of wire cables available, their specific applications, and how to choose the most appropriate one for your needs.

Industry expert Dr. John Smith, a leading authority on electrical installations, emphasizes, "Selecting the right wire cable not only ensures compliance with safety standards but also enhances the overall durability and functionality of electrical systems." With advancements in materials technology and increasing demands on energy efficiency, it is essential for both professionals and DIY enthusiasts to stay informed about the latest wire cable options and best practices. This introduction to wire cable selection aims to provide you with the key considerations needed to make informed decisions for your electrical projects, ensuring reliability and safety throughout their lifespan.

Understanding Different Types of Wire Cables for Electrical Use

When it comes to electrical projects, understanding the different types of wire cables available is crucial for ensuring safety and efficiency. Wire cables come in various types, each designed for specific applications. For instance, the most common types include THHN, NM, and UF cables. THHN wire is often used in commercial and industrial applications due to its durability and resistance to heat, while NM (non-metallic) cable is ideal for residential wiring within walls. UF (underground feeder) cable, as the name suggests, is suitable for direct burial applications, providing extra protection against moisture and external elements.

Additionally, choosing the right wire gauge is essential. The gauge indicates the wire's thickness; the lower the number, the thicker the wire. Thicker wires can handle more current, making them suitable for high-power devices. For example, 12-gauge wire is commonly used for lighting circuits and outlets, while 14-gauge wire is often used for light fixtures and smaller devices. It's also important to consider the insulation rating, which protects against various environmental factors, ensuring the cable's longevity and reliability. With a clear understanding of these types and specifications, you can make informed decisions for your electrical projects.

How to Choose the Right Wire Cable for Your Electrical Projects

Assessing Voltage and Current Requirements for Your Project

When embarking on electrical projects, the first crucial step is to assess the voltage and current requirements specific to your application. Voltage ratings define the maximum potential difference that a cable can safely handle, while current ratings determine the amount of electric current that can pass through the wire without overheating. Understanding these two parameters is essential to ensure not only the safety but also the efficiency of your electrical system.

To accurately evaluate your project's needs, start by identifying the electrical devices you'll be using and their corresponding voltage and current specifications. This information is typically found in the product manuals or on labels attached to the devices. Once you have gathered this data, match it to the appropriate wire gauge and material that can accommodate the required load. Utilizing resources like the American Wire Gauge (AWG) chart can aid in selecting the right wire size, as it directly correlates to the current-carrying capacity and resistance to voltage drop over distance.

Proper wire selection facilitates optimal performance and prolongs the lifespan of your electrical components.

Evaluating Insulation Ratings and Materials for Safety

When selecting the right wire cable for electrical projects, one of the most critical factors to consider is the insulation rating. Insulation serves as a protective barrier, preventing electrical shock and short circuits. The National Electrical Code (NEC) outlines various insulation ratings, which indicate the temperature and voltage limits that a wire can handle safely. It's essential to evaluate these ratings based on the specific environmental conditions of your project, including exposure to heat, moisture, and chemicals, as these elements can significantly affect wire performance and safety.

In addition to insulation ratings, the material used for insulation is equally important. Common insulation materials include PVC, rubber, and thermoplastic elastomers, each offering distinct advantages. For instance, PVC provides good flexibility and resistance to abrasion, while rubber insulation is better suited for high-temperature applications. Understanding the properties of these materials can help ensure that the wire cable not only meets the required safety standards but also performs optimally in its intended application.

Always prioritize high-quality materials that are well-suited for your specific electrical requirements to ensure longevity and reliability in your projects.

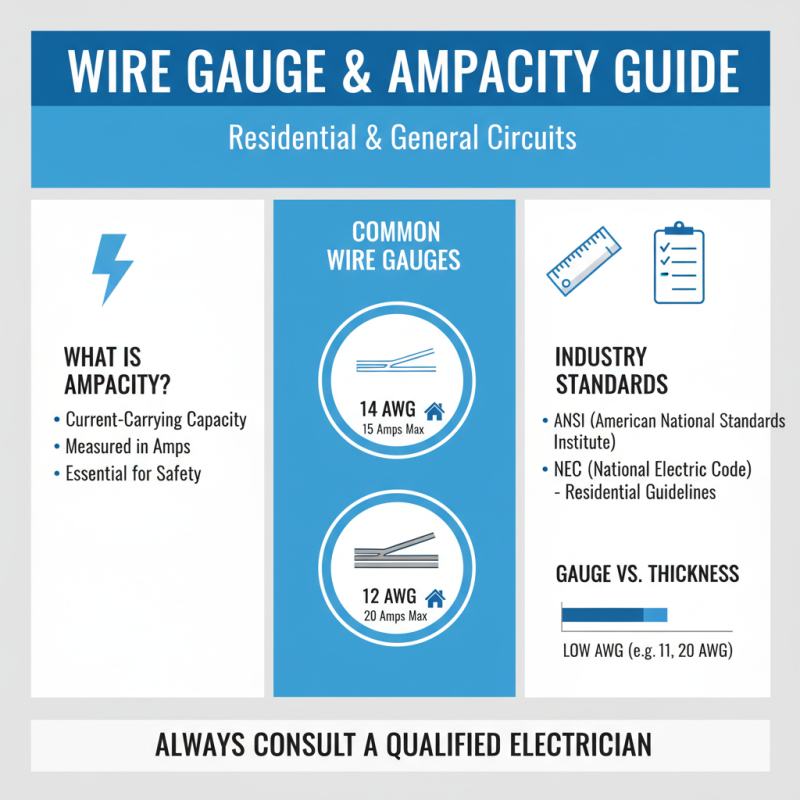

Selecting the Appropriate Gauge for Your Wiring Needs

When it comes to selecting the appropriate gauge for your wiring needs, understanding the ampacity, or current-carrying capacity, of different wire sizes is essential. The American National Standards Institute (ANSI) defines a set of standards that categorize wire gauges, typically ranging from 40 AWG (American Wire Gauge) which is used for small applications, up to 250 MCM (thousand circular mils) for heavy-duty electrical work. For residential projects, the National Electric Code (NEC) provides guidelines indicating that for a general circuit, a 12 AWG wire is standard for loads up to 20 amps, while a 14 AWG wire suffices for loads up to 15 amps.

Selecting the right gauge also involves understanding the voltage drop, particularly for longer runs of wire. A rule of thumb is that voltage drop should not exceed 3% for branch circuits to ensure efficiency and safety. For example, if you’re running a circuit over 100 feet, using a larger gauge, such as 10 AWG instead of 12 AWG, can help mitigate this drop. Data reported by the National Electrical Contractors Association (NECA) indicate that improper gauge selection accounts for a significant portion of electrical failures, emphasizing the importance of choosing the right size not just for performance but also for compliance with safety regulations. Proper gauge selection enhances durability and can prevent overheating, ultimately extending the life of your electrical installations.

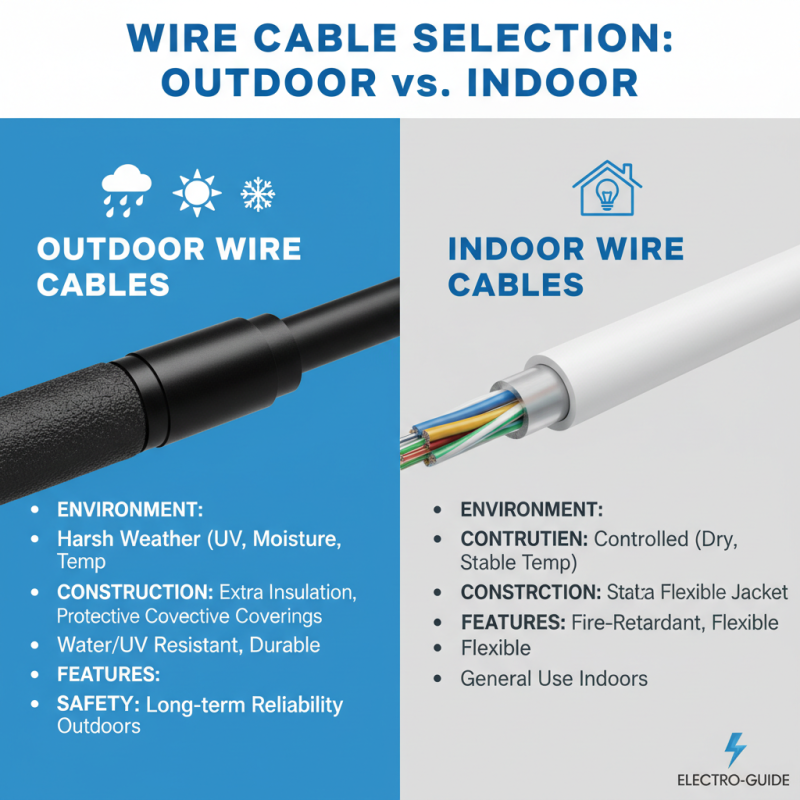

Important Considerations for Outdoor vs. Indoor Cable Selection

When selecting wire cables for outdoor versus indoor electrical projects, several important considerations come into play. First and foremost, the environment in which the cable will be used significantly impacts its construction. Outdoor cables are typically designed to withstand harsh weather conditions, including UV exposure, moisture, and temperature fluctuations. As a result, they often feature additional insulation and protective coverings to prevent damage from elements like rain, snow, and sunlight. These factors are crucial in ensuring long-term durability and safety in outdoor applications.

On the other hand, indoor cables are primarily focused on flexibility and ease of installation. They do not require the same level of protection from environmental factors, allowing for a more lightweight and manageable design. However, indoor installations must adhere to specific safety codes and standards to prevent risks such as overheating or electrical fires. Selecting the appropriate gauge and type for the intended use, whether for general wiring, lighting, or power supply, is essential in creating a safe and efficient electrical system. Understanding the differences between outdoor and indoor cable specifications will facilitate better decision-making in your projects.

Related Posts

-

Top 10 Power Wire Types You Need for Your Electrical Projects in 2023

-

Top 10 Tips for Choosing the Perfect Cable Harness for Your Project

-

Top 10 Best Control Wire Types for Optimal Performance and Durability

-

Top Uses of Flexible Cable in 2025 and Its Impact on Technology Development

-

How to Choose the Best Cable Solutions for Your Home and Office Needs

-

Understanding the Essentials of Cable Harness: A Comprehensive Guide for Beginners