How to Choose the Right Marine Wire for Your Boat

Choosing the right marine wire for your boat is crucial. It ensures safety and performance. According to marine electrical expert John Smith, "Using the proper marine wire can prevent electrical failures." Selecting marine wire isn’t just about specs.

Many boat owners overlook the importance of wire quality. Different applications require different types of marine wire. For example, tinned copper wire resists corrosion, making it ideal for saltwater environments. Yet, some users still buy regular wire, risking failures.

When considering marine wire, think about ampacity, insulation, and flexibility. Each factor plays a role in overall safety. While the choices may seem overwhelming, the wrong selection can lead to serious issues. Focus on your boat's needs. Investing time in this decision is always worth it.

Understanding Marine Wire Types and Their Specifications

When it comes to marine wiring, understanding the various types is crucial. There are several kinds of marine wire, including tinned and non-tinned options.

Tinned wire is highly resistant to corrosion. This makes it a preferred choice for marine environments. Non-tinned wire may suffice in less demanding situations. However, it could wear down much faster.

Different gauges are important too. Thicker wires can carry more current. They are essential for power-hungry devices. For example, a 10-gauge wire can support larger electrical loads. If you choose a thinner gauge, it might lead to overheating. This can be dangerous and cause damage.

Consider insulation types as well. Heat-resistant insulation helps in high-temperature areas. In contrast, a flexible jacket is ideal for tight spaces. These details might seem small, yet they greatly affect performance. You'll need to evaluate your boat's specific requirements. Ignoring any of these factors can lead to subpar choices. Take time with your selection. It can save you from costly repairs down the line.

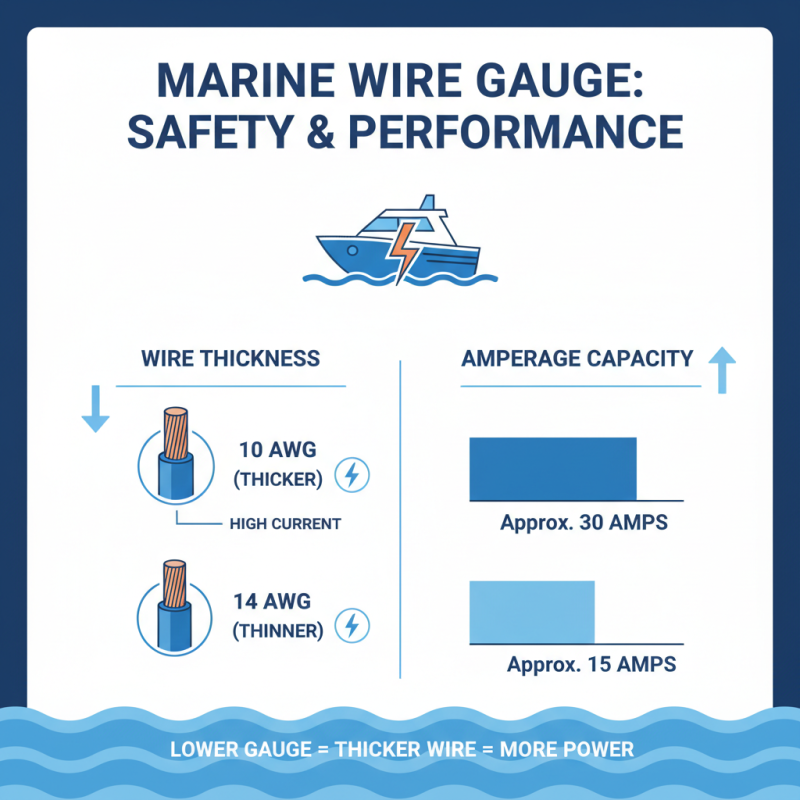

Identifying Correct Wire Gauge Using the American Wire Gauge (AWG) System

Choosing the right marine wire is critical for boat safety and performance. Understanding wire gauge is vital. The American Wire Gauge (AWG) system provides a standard for measuring wire thickness. A lower gauge number means a thicker wire, which can handle more current. For example, a 10 AWG wire can carry about 30 amps safely, while a 14 AWG wire is limited to around 15 amps.

Incorrect wire sizing can lead to overheating and failures. Many boat owners opt for smaller gauge wires to save weight. This is often a risky decision. Even slight miscalculations can lead to severe consequences. Industry reports show that nearly 25% of electrical failures on boats stem from improper wiring. It’s essential to perform a load calculation based on your boat’s equipment. Ensure you are mindful of both the distance the current travels and the total amperage.

Consider common mistakes. Some may disregard the length of the wire run. Longer distances require thicker wires. A wire that is too thin for the distance will heat up quickly. Boats should always have a safety margin in their wiring. Adopting the right gauge wire for your needs can prevent potential hazards. Evaluate your current setup carefully and invest in safety.

Evaluating Voltage Drop and Its Impact on Marine Electrical Systems

When selecting marine wire, voltage drop is a critical factor. It refers to the reduction in voltage as electricity travels through the wire. Excessive voltage drop can impact the performance of electrical components on your boat. According to industry standards, voltage drop should not exceed 3% for power circuits and 10% for lighting circuits. This range ensures efficient operation and longevity of your equipment.

Using the wrong wire gauge can lead to significant voltage drop. For instance, a 20-foot run of 12 AWG wire could result in a 3% drop at 20 amps. In contrast, an 18 AWG wire would exceed this limit. This discrepancy can lead to underperformance of electronics, affecting navigation systems or lights. The marine environment compounds these effects. Corrosion and temperature fluctuations can further deteriorate wire quality, leading to unpredictable voltage issues.

Choosing the right length is also vital. Longer runs increase resistance, resulting in elevated voltage drops. It's important to measure your wire needs accurately. Overestimating could waste materials and increase costs. Underestimating can lead to potential system failures. Regular inspections of your wiring can reveal wear and tear. Attention to these details can prevent bigger problems down the line.

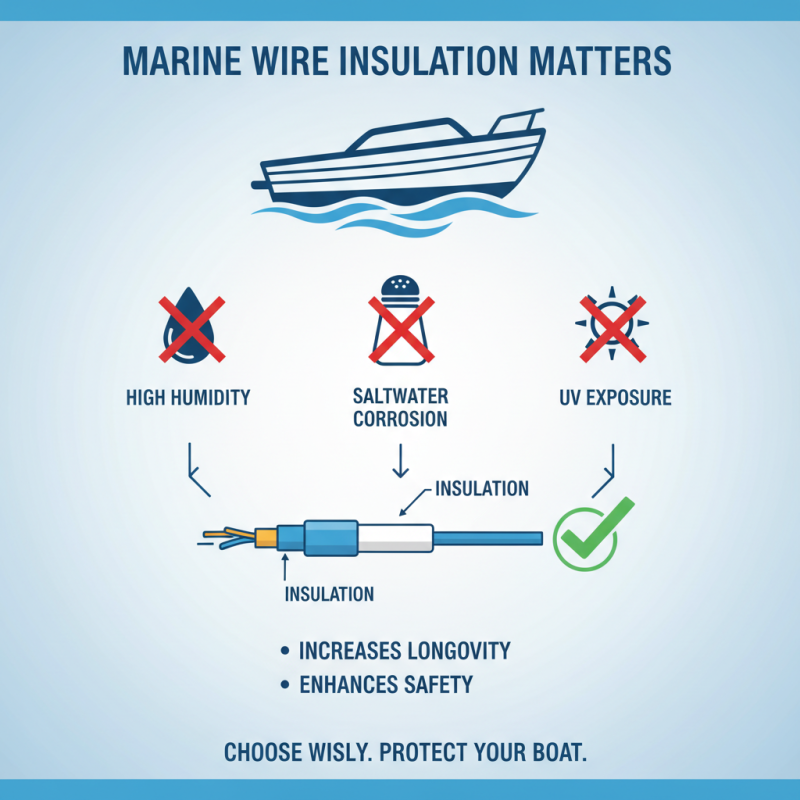

Selecting Insulation Ratings for Enhanced Longevity in Marine Environments

When choosing marine wire, insulation ratings are crucial. Boats face harsh environments. High humidity, saltwater, and UV exposure can degrade wire insulation over time. The right insulation increases longevity and safety.

Many industry studies indicate that using wire with proper ratings can extend lifespan significantly. For instance, tinned copper wire with high-quality insulation can last up to 30% longer in marine conditions. The American Boat and Yacht Council (ABYC) emphasizes that selecting the right insulation, such as cross-linked polyethylene, enhances resistance to environmental factors.

Tips: Always check insulation ratings. Look for UL 1426, which is specifically designed for marine applications. Consider the wire’s temperature rating. Opt for products that can withstand high heat. This can prevent premature failure.

Choosing the wrong wire might seem trivial, but it can lead to issues. Insufficient insulation can cause short circuits. Some boaters overlook this detail, leading to unnecessary repairs. Paying attention to these aspects is essential for boat safety and functionality.

Ensuring Compliance with ABYC and NMMA Standards for Marine Wiring

When choosing marine wire for your boat, compliance with ABYC and NMMA standards is crucial. These standards ensure safety and reliability in the marine environment. They cover various aspects, including materials and wire insulation. Selecting the right wire requires understanding the specific requirements for your vessel.

It’s important to consider wire size and type. Many boaters overlook these details. Proper gauge wire improves efficiency and reduces overheating risks. For example, using a smaller gauge wire than required can lead to serious problems. But getting the right insulation is just as important. Choose wire with insulation rated for marine use.

One common mistake is not accounting for environmental factors. Marine environments can be harsh. Corrosion and moisture can degrade standard wiring. Regular checks, and perhaps even unexpected replacements, might be necessary. After all, it's about ensuring safety on the water. The right wiring choices can help avoid hazards. Reflect on your choices to guarantee compliance and safety standards, helping your boat perform at its best.

How to Choose the Right Marine Wire for Your Boat - Ensuring Compliance with ABYC and NMMA Standards for Marine Wiring

| Wire Gauge | Recommended Amperage (A) | Application | Insulation Type | Standards Compliance |

|---|---|---|---|---|

| 16 | 3-10 | Lighting | Tin-Plated Copper | ABYC, NMMA |

| 14 | 10-15 | Instrumentation | Cross-Linked Polyethylene | ABYC, NMMA |

| 12 | 15-20 | Power Distribution | PVC Insulation | ABYC, NMMA |

| 10 | 30-40 | Starter Cables | Rubber Insulation | ABYC, NMMA |

| 8 | 40-55 | Large Appliances | Multistrand Copper | ABYC, NMMA |

Related Posts

-

Ultimate Guide to Wire Harness Top Tips for Installation and Maintenance

-

Understanding the Essentials of Cable Harness: A Comprehensive Guide for Beginners

-

Best Electrical Wire Types for Your Projects?

-

The Ultimate Guide to Understanding Control Wires: Applications, Types, and Best Practices

-

Top 10 Cable Wire Cable Types for Your Home and Business Needs

-

Essential Tips for Understanding Lead Cable Applications?