2025 How to Choose the Right Cable Wire for Your DIY Projects

In the evolving landscape of DIY projects, selecting the appropriate cable wire is critical for ensuring both safety and efficiency. According to a 2022 market report by Global Market Insights, the global cable wire market is expected to exceed $200 billion by 2025, driven by increasing construction activities and a growing emphasis on sustainable energy solutions. This remarkable growth highlights the significance of understanding the intricacies associated with choosing the right cable wire for any project, from home renovations to intricate electrical installations.

Expert insights emphasize the importance of proper selection, as noted by Dr. Emily Carter, a leading authority in electrical engineering. She states, "Choosing the right cable wire is not just about function; it’s about ensuring long-term reliability and performance in your projects." The diversity of cable wire types, such as copper, aluminum, and fiber optic, further complicates the decision-making process, and it's essential for DIY enthusiasts to consider factors such as conductivity, insulation, and installation requirements. As we delve deeper into the nuances of cable wire selection, this guide aims to equip you with the knowledge needed to make informed choices that will elevate your DIY endeavors.

Understanding Different Types of Cable Wires for DIY Projects

When embarking on DIY projects, understanding the various types of cable wires available is crucial for ensuring the success and safety of your work. Different projects require different types of cables, each designed with specific functions in mind. For instance, if you are working on electronic projects, you might need insulated copper wire, which is excellent for carrying electrical current and is available in various gauges depending on the load. The gauge represents the thickness of the wire, influencing its capacity to carry current safely.

Additionally, for projects involving outdoor lighting or landscaping, weather-resistant types such as low-voltage landscape wire or direct burial cable should be considered. These cables are designed to withstand moisture and temperature changes, ensuring durability over time. Another essential type to consider is the multi-conductor cable, which allows for multiple circuits to run together, making it ideal for complex systems.

By understanding the specific needs of your project and selecting the appropriate cable wire, you can enhance both the functionality and safety of your DIY endeavors.

Assessing Your Project Requirements: Voltage, Current, and Length

When embarking on a DIY project, understanding the basic electrical requirements is essential to ensure safety and functionality. One of the first factors to consider is the voltage your project will operate on. Different devices and applications require different voltage levels, and choosing a cable wire that can handle the specified voltage is critical. Insufficient voltage ratings can lead to overheating and potential failure of the wire, which might endanger your project or home.

Next, assessing the current load is equally important. Each cable wire is rated for a certain amount of current, typically measured in amperes. The wire you choose must be capable of carrying the total current your project will draw. Exceeding this rating can result in dangerous scenarios, including fire hazards. Always calculate the total current requirements of all devices and components involved in your project to select the appropriate wire gauge that provides sufficient capacity.

Finally, the length of the cable wire plays a significant role in your project. Longer lengths can introduce voltage drop, which diminishes the voltage delivered to your device and can affect its performance. It's essential to account for the distance the electricity must travel and select a wire that compensates for any potential losses. By taking into account these three critical aspects—voltage, current, and length—you can ensure your DIY project operates safely and effectively, resulting in a successful outcome.

2025 How to Choose the Right Cable Wire for Your DIY Projects

| Project Type | Voltage (V) | Current (A) | Cable Length (ft) | Wire Gauge |

|---|---|---|---|---|

| LED Lighting | 12 | 2 | 50 | 18 AWG |

| Home Appliances | 120 | 15 | 30 | 14 AWG |

| Power Tools | 240 | 20 | 100 | 12 AWG |

| Solar Panel System | 48 | 10 | 200 | 10 AWG |

| Television | 120 | 3 | 15 | 18 AWG |

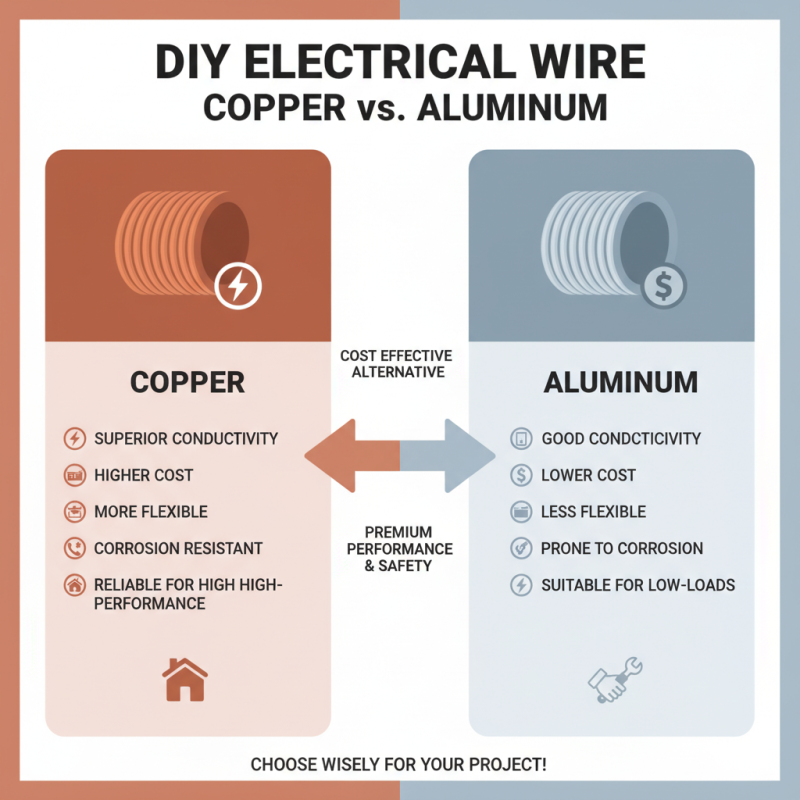

Selecting the Right Material: Copper vs. Aluminum Wire

When embarking on a DIY project that requires electrical installation, one of the key decisions you'll need to make is selecting the right wire material. The two most common options are copper and aluminum, each with distinct advantages and disadvantages. Copper wire is renowned for its superior conductivity, meaning it can efficiently carry electrical current with minimal energy loss. This makes it an ideal choice for high-performance applications, especially in environments where reliability is paramount.

On the other hand, aluminum wire is significantly lighter and typically more affordable than copper. While it has lower conductivity compared to copper, advancements in technology have led to specialized techniques that can enhance aluminum's performance in various scenarios. It's important to consider the specific requirements of your project—such as length, current capacity, and environmental conditions—when making your selection.

Tips: Consider the amperage your project requires; copper is better for higher amperages due to its conductivity. If cost constraints are crucial, aluminum may be the way to go, but ensure that the connections are done correctly to avoid potential issues. Always check local codes and regulations regarding wire materials to ensure safety and compliance in your DIY endeavors.

Evaluating Insulation Types for Safety and Durability

When selecting the right cable wire for your DIY projects, understanding the insulation types is crucial for ensuring safety and durability. Insulation serves as a protective barrier, safeguarding the conductor from environmental elements, physical damage, and electrical hazards. The choice of insulation material can significantly impact the wire's performance in various settings, so it's essential to assess the suitability of each type for your specific application.

For indoor projects, PVC (Polyvinyl Chloride) insulation is commonly used due to its affordability and ease of handling. It provides adequate protection against moisture and is resistant to many chemicals. However, if your project requires exposure to extreme temperatures or outdoor conditions, consider using thermoplastic elastomer (TPE) or cross-linked polyethylene (XLPE) insulation, which offer superior thermal stability and weather resistance.

Tips: Always check the temperature rating of the insulation type to ensure it meets your project's needs. Additionally, when dealing with projects that might encounter physical wear and tear, opt for wires with thicker insulation to enhance durability. Lastly, if you’re unsure, consult the manufacturer's specifications to match the insulation type to your intended use and environment.

Tips for Properly Sizing Cable Wires for Optimal Performance

When embarking on a DIY project, selecting the correct cable wire is crucial for ensuring both functionality and safety. One of the most important factors to consider is the wire's gauge, which determines its capacity to carry electrical current. Generally, a lower gauge number corresponds to a thicker wire that can handle higher current loads. For instance, if your project involves powering high-demand devices, opting for a lower gauge wire will help prevent overheating and potential hazards. Conversely, if your project involves low-power applications, a higher gauge wire would be more suitable and cost-effective.

In addition to wire gauge, it's essential to account for the length of the wire run. The longer the wire, the more resistance the current faces, which can lead to voltage drops that affect performance. To mitigate this, you may need to use a thicker wire if the distance exceeds a certain threshold. Moreover, considering the environment where the wire will be installed—such as exposure to moisture or extreme temperatures—can guide the choice of insulation type, ensuring durability and safety. By carefully sizing your cable wires according to these guidelines, you can optimize the performance of your DIY projects while minimizing the risk of electrical issues.

Related Posts

-

2025 Top Cable Harness Innovations and Trends You Need to Know

-

How to Choose the Best Cable Solutions for Your Home and Office Needs

-

2025 Top 5 Wire Pulling Ropes for Easy and Efficient Cable Installation

-

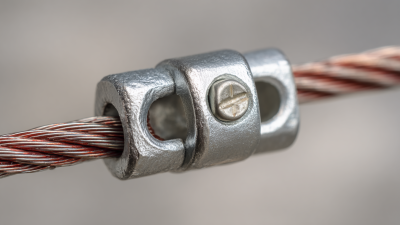

How to Choose the Right Wire Clamp for Your Projects: A Complete Guide

-

Why You Should Use Wire Clips for Effective Organization and Storage Solutions

-

Understanding the Importance of Cable Clamps in Modern Electrical Installations