How to Choose the Right Cable Clamp for Your Project Needs

When embarking on a project that involves managing cables, selecting the appropriate cable clamp is a crucial step that can significantly impact the overall efficiency and safety of your installation. Cable clamps serve the essential function of securely holding cables in place, preventing tangling, and reducing the risk of damage from excessive movement or strain. With a variety of options available, including different materials, sizes, and designs, the process of choosing the right cable clamp can be daunting.

Understanding the specific requirements of your project is key to making an informed decision. Factors such as cable type, environmental conditions, and mounting surfaces must all be considered. Additionally, proper cable clamp selection can enhance organization within your workspace and ensure compliance with various safety standards. In this guide, we will explore the essential considerations to keep in mind when selecting cable clamps, providing you with the knowledge needed to make the best choice for your unique project needs.

Factors to Consider When Selecting Cable Clamps

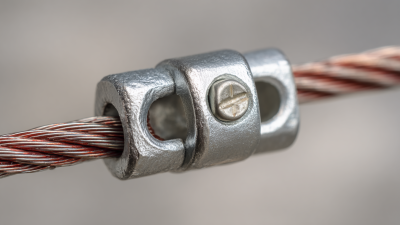

When selecting cable clamps for your project, several key factors must be considered to ensure optimal performance and safety. First, it is crucial to assess the cable diameter and type. According to industry reports, proper cable clamp selection can reduce the risk of cable damage by up to 40%. For instance, a clamp that is too small could restrict cable movement and lead to wear, while one that is overly large can compromise stability. Understanding the specific requirements of your cables, including insulation type and environmental exposure, will help in selecting the right size and style of clamp.

Additionally, consider the material of the cable clamps. Common materials include stainless steel, plastic, and rubber. Research indicates that clamps made from stainless steel offer superior strength and resistance to corrosion, making them an excellent choice for outdoor and industrial applications. In contrast, rubber clamps can provide better insulation and flexibility for electrical cables. Therefore, the project environment—be it indoor, outdoor, or in high-temperature areas—should influence your material choice significantly.

Tips: Always ensure that the clamps you choose meet the necessary safety standards relevant to your project. Moreover, consider the installation method—nylon clamps may require adhesive backing for easy application, while metal clamps may need screws or bolts. Finally, consult recent industry findings or manufacturer guidelines to confirm that the clamps align with your project specifications and safety requirements.

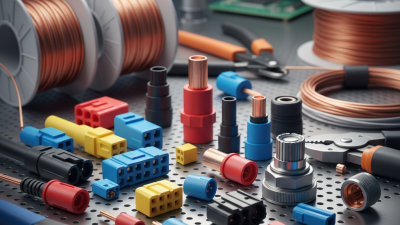

Types of Cable Clamps Available on the Market

When selecting a cable clamp for your project, it's crucial to understand the various types available on the market. Cable clamps can be categorized into several different types based on their material and design. Common materials include steel, plastic, and rubber, each offering unique advantages.

According to a recent industry report by the International Association of Electrical Inspectors, steel clamps are renowned for their durability and strength, making them ideal for heavy-duty applications where cable integrity is critical.

Another prevalent type is plastic cable clamps, which are often favored for their lightweight nature and corrosion resistance. These clamps are suitable for indoor applications and environments that do not experience extreme conditions. A report by MarketsandMarkets highlights that the plastic cable clamp segment is expected to grow significantly due to the increased demand in construction and telecommunications, projected to reach a market value of over

$2 billion by 2025.

Furthermore, rubber clamps offer excellent grip and can absorb vibration, making them a great choice for situations where cables are subject to movement or shock, thus enhancing the longevity of the installation.

Selecting the right cable clamp involves considering not only the type but also the specific requirements of your application, such as environmental exposure and load-bearing capacity. For instance, if you're working in an outdoor or corrosive environment, investing in stainless steel or specially coated clamps might be the best choice. Understanding these options ensures that you align the clamp selection with the functional and safety needs of your project.

Material Considerations for Cable Clamps

When selecting the appropriate cable clamp for your project, material considerations play a pivotal role in ensuring durability and performance. The most common materials used for cable clamps include stainless steel, plastic, and aluminum, each offering distinct advantages depending on the specific requirements of your application. Stainless steel, known for its high tensile strength and resistance to corrosion, is ideal for outdoor or marine settings where exposure to moisture is a concern. Its robust nature makes it a reliable choice for heavy-duty applications, ensuring that cables are securely fastened even under challenging environmental conditions.

On the other hand, plastic cable clamps provide a lightweight and cost-effective alternative suitable for indoor use or less demanding environments. They are often resistant to chemicals and humidity, making them a great option for applications where corrosive materials might be present. However, plastic clamps may not withstand higher temperatures or heavy loads as effectively as their metal counterparts. Aluminum offers a middle ground, combining lightweight properties with moderate strength, making it suitable for various applications. Ultimately, understanding the specific environmental conditions and load requirements will guide you in selecting the right material for your cable clamp, ensuring optimal performance and longevity in your project.

How to Choose the Right Cable Clamp for Your Project Needs - Material Considerations for Cable Clamps

| Material Type | Corrosion Resistance | Temperature Resistance | Flexibility | Price Range |

|---|---|---|---|---|

| Plastic | Good | Low (up to 80°C) | High | $ |

| Steel | Moderate (varies with coating) | High (up to 300°C) | Low | $$ |

| Aluminum | Good | Moderate (up to 150°C) | Medium | $$$ |

| Stainless Steel | Very Good | Very High (up to 500°C) | Low | $$$$ |

Sizing and Compatibility of Cable Clamps for Different Projects

When selecting the right cable clamp for your project, understanding sizing and compatibility is crucial to ensure that your setup is both safe and effective. Cable clamps come in various sizes and materials, making it essential to know the diameter of the cables you plan to use. A properly sized clamp should hold the cables securely without causing any damage. Ideally, the clamp should fit snugly around the cable, leaving no excessive room that could lead to movement or wear over time.

Tips for choosing the right size include measuring the cable’s diameter accurately and considering the environment in which the clamp will be used. If your project involves outdoor applications, make sure to select clamps made from weather-resistant materials. For projects with multiple cables, look for adjustable clamps that can accommodate varying diameters, ensuring versatility in your installation.

Compatibility is another key factor. Different projects might require specific types of clamps, such as those designed for high-temperature environments or for use with certain types of insulation. Always verify that the clamp material aligns with the properties of the cables, such as flexibility or resistance to chemicals. This ensures that your cable management system functions efficiently and remains durable over time.

Common Applications of Cable Clamps in Various Industries

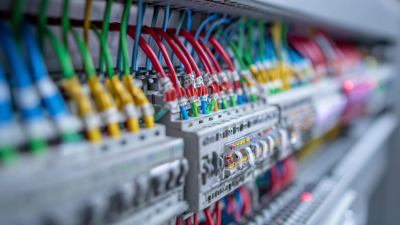

Cable clamps play a crucial role in various industries by ensuring the secure organization and management of electrical wires and cables. In construction, these clamps are vital for holding cables in place during the installation of lighting and power systems. Proper use of cable clamps can prevent damage to the cables, reduce risks of electrical hazards, and enhance the overall safety of the construction site. Similarly, in the telecommunications sector, cable clamps are essential for routing and securing communication cables, ensuring reliable connectivity and reducing interference.

In the automotive industry, cable clamps are used extensively to hold wiring harnesses in place, safeguarding them from heat and potential wear from engine components. This not only ensures the proper functioning of various electronic systems within vehicles but also contributes to the longevity of the electrical components. Additionally, in the manufacturing sector, cable clamps help manage equipment wiring in machinery, promoting an organized workspace and minimizing the risk of accidents caused by tangled or exposed cables. Each application highlights the significance of selecting the appropriate type of cable clamp to meet the specific project requirements and industry standards.

Common Applications of Cable Clamps in Various Industries

Related Posts

-

Understanding the Importance of Cable Clamps in Modern Electrical Installations

-

2025 How to Choose the Best Wire Cable Connectors for Maximum Efficiency

-

The Ultimate Guide to Understanding Control Wires: Applications, Types, and Best Practices

-

What is a Wire Cable Connector? Understanding Types and Applications

-

2025 Top 5 Wire Pulling Ropes for Easy and Efficient Cable Installation

-

How to Choose the Right Wire Cable for Your Electrical Projects