2026 How to Choose the Best Aluminum Composite Panel Manufacturers?

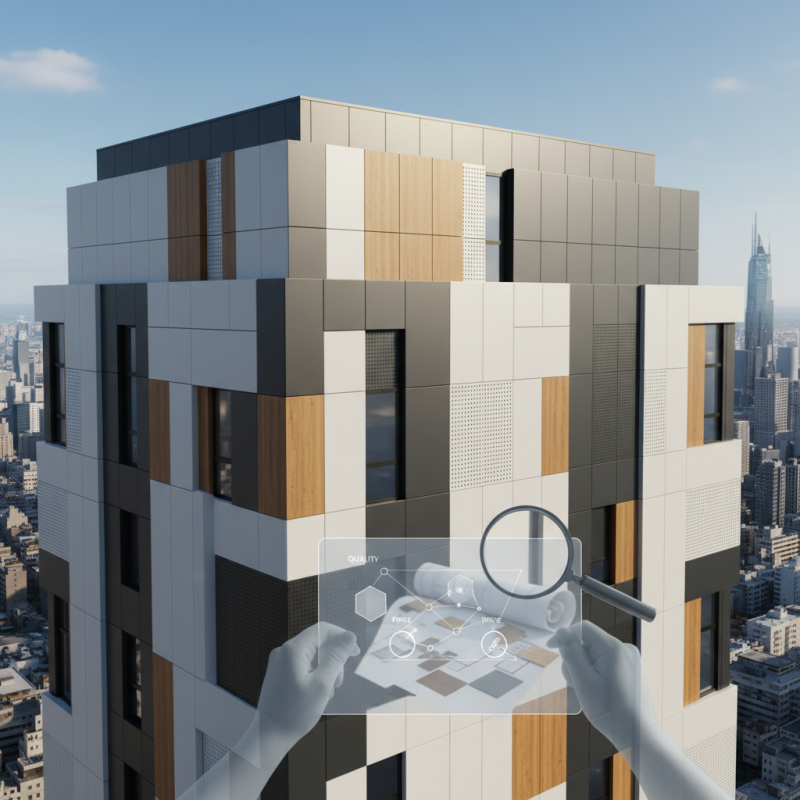

Choosing the right aluminum composite panel manufacturers can greatly impact your project. With so many options available, it becomes essential to evaluate them carefully. These panels offer aesthetic appeal and durability, making them a popular choice in construction and design.

Quality and price are two critical factors when selecting manufacturers. Some may promise low prices but lack quality. It is vital to check reviews and past projects of potential suppliers. This way, you can gauge their reliability and craftsmanship.

Moreover, consider the range of products offered. Not all aluminum composite panel manufacturers provide the same styles or finishes. Think about what you need for your specific application. Sometimes, companies may seem impressive but may not meet your unique requirements. Taking time to reflect on your choices can lead to better outcomes.

Factors to Consider When Selecting Aluminum Composite Panel Manufacturers

When choosing aluminum composite panel manufacturers, it's essential to consider various factors. First, assess the manufacturer’s experience in the industry. Companies with a solid track record are more likely to deliver quality products. According to a recent market analysis, manufacturers with over ten years of experience show a 35% higher customer satisfaction rate.

Quality control processes are vital too. Inspecting their production methods gives insights into their reliability. Look for manufacturers that adhere to international standards. It’s reported that companies following strict quality control achieve a defect rate as low as 1%.

Tips: Always request samples to evaluate material quality before making a larger commitment. Don't hesitate to ask for certifications and compliance documents. Also, evaluate their customer service. Poor communication can lead to misunderstandings.

Reassessing price vs. quality is crucial. Lower prices may indicate inferior materials. However, high prices don’t always guarantee superior quality. Always weigh the evidence carefully. An ideal choice blends reliability with performance and cost-effectiveness.

2026 How to Choose the Best Aluminum Composite Panel Manufacturers?

| Factor | Description | Importance Level |

|---|---|---|

| Experience | Years of operation in the industry. | High |

| Quality Certifications | Relevant certifications (ISO, etc.) that ensure product quality. | High |

| Material Sourcing | Use of high-quality materials in manufacturing. | Medium |

| Customization Options | Ability to customize panels according to client needs. | Medium |

| Customer Support | Availability of support before and post-sale. | High |

| Lead Time | Time taken to fulfill orders. | Medium |

| Pricing | Competitiveness of pricing compared to market standards. | High |

Evaluating Manufacturer's Experience and Industry Reputation

When choosing aluminum composite panel manufacturers, evaluating their experience and reputation is crucial. A recent industry report indicates that over 70% of buyers prioritize a manufacturer’s years in business. Experienced manufacturers typically have more refined processes and better quality control. They are likely to understand market trends and customer needs more effectively.

Reputation plays a similar role. According to a survey by the Construction Specification Institute, 65% of project managers trust recommendations based on reputation alone. Positive reviews from prior clients signal reliability. Visiting trade shows, reading industry publications, or seeking referrals can provide insights into a manufacturer’s standing. However, it's essential to discern genuine reviews from biased feedback; not all glowing reviews are trustworthy.

A vast majority of manufacturers claim high quality, but not every claim holds up. The construction industry requires due diligence. Reviewing case studies or requesting samples can reveal discrepancies between advertisement and reality. Engaging directly with past clients helps identify consistent issues, such as poor communication or delays in delivery. This can prevent future headaches and ensure project success.

Evaluating Aluminum Composite Panel Manufacturers

This chart evaluates different manufacturers of aluminum composite panels based on their experience, industry reputation, customer satisfaction, and product range. The comparison helps in determining which manufacturers stand out in these crucial areas.

Understanding the Quality Assurance Processes in Panel Production

When considering aluminum composite panels, understanding the quality assurance processes is vital. Quality assurance ensures that panels meet industry standards. Look for manufacturers with robust testing mechanisms. These may include dimensional checks, surface inspections, and adhesion tests.

Tips: Always check if a manufacturer has certifications. This reflects a commitment to quality. Ask for samples to gauge material quality before deciding.

During production, a manufacturer must adhere to strict protocols. This includes monitoring raw material sources and conducting regular audits of processes. However, not all manufacturers are consistent. Some may overlook minor details, leading to potential defects.

Tips: Don’t hesitate to ask about their quality assurance processes. A reliable manufacturer will be transparent. Investigate customer reviews for insights on their experiences with panel quality.

Assessing Product Variety and Customization Options Available

When selecting aluminum composite panel manufacturers, assessing product variety is essential. A diverse range of options allows manufacturers to meet specific project needs. According to a recent industry report, nearly 70% of architects prioritize customization in building materials. Customization enhances design possibilities and ensures the panels fit the project's vision.

Customization options can include colors, finishes, and sizes. Many manufacturers provide color-matching services to help clients achieve their desired aesthetic. Data shows that 45% of construction projects involve unique panel dimensions. This emphasizes the need for manufacturers to offer tailor-made solutions. However, some manufacturers might have limited capabilities, which can restrict creative designs.

Furthermore, not all manufacturers have the same level of expertise in customization. It's crucial to research and assess their past projects. Some companies may advertise extensive options but fail to deliver on quality or timely production. A balance between variety and quality assessment is vital for successful outcomes. Consider visiting manufacturers’ facilities if possible. It's an opportunity to observe their processes and expertise firsthand.

Analyzing Customer Reviews and Testimonials for Reliable Insights

When selecting aluminum composite panel manufacturers, customer reviews play a vital role. According to a recent industry report, 73% of consumers trust online reviews as much as personal recommendations. This highlights the importance of analyzing feedback from past clients. Companies often list testimonials on their websites, but those can be biased. Seeking reviews on independent platforms gives a clearer picture.

Look for patterns in feedback. If many customers mention durability, this indicates reliability. However, be cautious of overly positive comments. Fake reviews can mislead potential buyers. A significant number of respondents in a 2022 survey noted dissatisfaction due to misleading information. Real user experiences provide insights into quality and service.

Pay attention to the details in the reviews, such as specific project outcomes. Customers frequently share both successes and setbacks. For instance, a review may mention the ease of installation but also issues with color consistency. Reflecting on such feedback can help you make a more informed decision about the manufacturer.